HC is designing shell and tube heat exchanger for customers

Recently, HC Petroleum Equipment received an inquiry about shell and tube heat exchanger. After understanding the operating pressure, temperature, fluid properties, scaling and other factors from users, our technical team is carrying out customized design.

Shell and tube heat exchanger is widely used in the petrochemical industry. It has the advantages of strong structure, excellent adaptability, a wide range of materials, easy to clean, high-temperature and high-pressure resistance, etc. According to the structural features, it can be divided into the following two categories:

1.Rigid structure of shell and tube heat exchanger: it is also known as a fixed tube plate type, which can be divided into single tube pass and multitube pass. It is simple and compact in structure with low cost and wide application, and the disadvantage is that the outer tube cannot be cleaned mechanically.

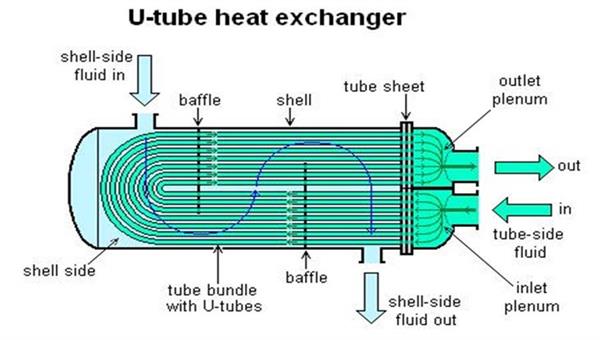

2.Shell and tube heat exchanger with temperature-difference compensation device: it can make the heated part expand freely. The structure can be divided into floating head heat exchanger and U-tube heat exchanger. Each of these types has advantages and disadvantages. For more details, please refer to Types and Differences of Heat Exchangers.

Due to the wide application of shell and tube heat exchangers, a series of standards have been developed for the convenience of design, manufacture, installation and use. However, in view of the different needs of users, we design and manufacture according to the actual needs in addition to the relevant specifications and standards.

Our engineering team has rich experience and is able to give the most cost-effective design scheme after fully considering the user's working environment and operation costs. HC hereby appreciates the trust of users, we will give full play to the technical advantages and provide users with the best equipment and services.