Gas filter separator commonly used in natural gas pipeline

When the natural gas is extracted from the formation, it will carry a large amount of gas or solid impurities. After the long-distance transportation of natural gas in the pipeline, the main impurities in the gas are corrosion products and iron dust powder, which is difficult for separators to separate. Therefore, the gas filter is often used in the gas transmission station to solve the problem of gas separation and dust removal.

When the water-containing natural gas enters the dry filter, the glass fiber is wetted by the liquid and the electrostatic effect is significantly reduced, so is the filtering effect of the dry filter. To this end, a filter separator can be used to remove the liquid solid impurities of water-containing natural gas.

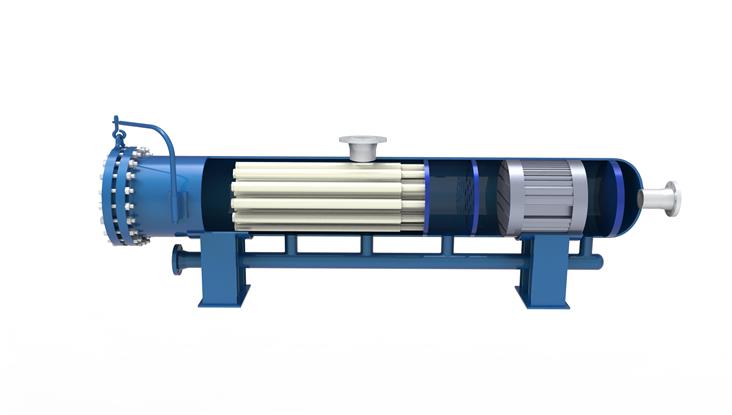

The filter separator is mainly composed of cylindrical glass fiber filter element and stainless steel wire demisting screen, which can be horizontal or vertical, and the most common type is horizontal.

Filtration separators are widely used in gas pipelines and gas treatment plants (such as acid removal plants). After passing through the filter, the separator captures liquid and condensed hydrocarbons from the absorber. In the gas treatment, sufficient inlet separators and filter separators are required to prevent foaming due to chemical contamination. If the absorber is located downstream of the amine unit, glycol unit or compressor, a filter separator is required.

HC has unique technology in the design and manufacture of filter separators. Our engineering team is able to face any challenge and will provide the most reasonable solution according to the specific needs of customers. Please do not hesitate to contact us for more information.