How does Production Separator work?

Production Separator is designed to separate feed inlet media to gaseous and liquid phases in oil & gas production facilities. Production Separators are either 2-phase or 3-phase depending on the operation requirements and separability of fluids. Production Separators are widely used in Early Production Facilities to separate free gas from crude oil, and crude oil from water (produced water). After separation, free gas (associated gas) flows out through gas-outlet nozzle on the top of separator vessel, while crude oil is delivered to secondary separation or dehydration unit, where crude oil additionally treated to remove remained water. Produced water will flow to water-treatment unit, where water is treated by removing small contents of liquid hydrocarbons and reinjected to wells through injection wellhead assemblies or disposed for other use.

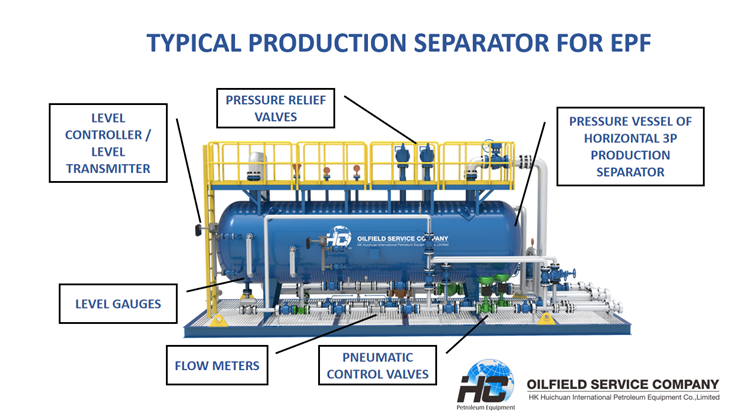

Control and Automation System of Production Separators is either digital or mechanical, and consists of level controllers or level switches, control valves, pressure controllers, pressure and temperature transmitters, flowmeters and other instrumentation. Inlet and outlet pipes contain manual ball valves, while some production facilities ball valves with actuators. Type of open/close valves depends on the initial design and client’s preferences. HC suggests ball valves, while globe or plug valves also available in HC’s offering range. Emergency Shutdown System (ESD) consists of pneumatic or hydraulic-actuated ball valve which closes inlet line in case of excessive flow, pressure or temperature is detected.

Separator Vessel consists of several internals, which increase separation efficiency. Welded internals are usually designed from the same material as separator vessel, while removable internals are advised to be made from stainless-steel (SS 316). Sand jetting system may be required in some production facilities where excessive amount of sand and solids are present. Design and configuration of 2 & 3P separators shall be done based on flowrate, pressure, temperature, composition of media, operational distinguishing characteristics and many other factors that may influence the price. Feel free to contact HC Petroleum Equipment for technical assistance and more information.