HC Petroleum Equipment offers solutions for flare gas NGL recovery

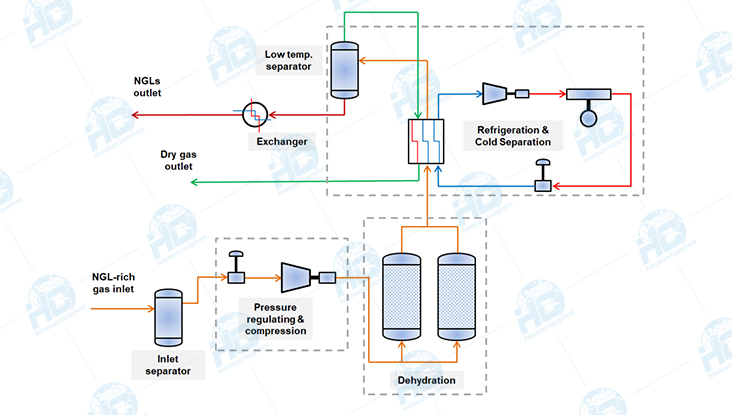

Flare Gas NGL Recovery Unit is designed to recover valuable natural gas liquids (NGLs) from natural gas which would normally be burned by the flaring systems. Flare Gas NGL Recovery Unit, as known as Flare Gas Recovery System (FGRS), allows gas operators to increase profit by selling recovered NGLs, meeting gas pipeline specification, and reduce impact on environment.

Configuration and price of NGL Recovery Units depends on many factors, such as flow rate; NGL volume in natural gas; pressure; temperature (working & environment); non-hydrocarbons volume in feed gas stream; requirements to final products; special requirements of the clients to configuration; automation and control. Our flare gas liquid recovery units are ideal to handle flare gas, associated gases, low pressure and low flow rate to recover Y-grade NGL, and condition outlet dry gas/lean gas for next disposal. After NGLs are recovered, they are transported by LPG tanks to nearest petrochemical facility, allowing fast investment turnover, maximize profits from operation, and reduce impact on environment.

Our manufacturing facility in China is ISO- and ASME-certified, which ensures state-of-art manufacturing and quality assembly. Our engineers conduct professional calculations using modern technology and software. Our project managers will provide immediate assistance with your inquiry and ensure that project is within mutually agreed schedule. Feel free to contact HC Petroleum Equipment for more information about NGL recovery solutions, Flare Gas Recovery Systems (FGRS), gas dehydration units (mol sieve, TEG), NGL fractionation, gas sweetening units (H2S scavenger, amine sweetening, mol sieve sweetening), and many other solutions for natural gas production and processing. We ensure performance quality, fast delivery and favorable price.