Comparison between horizontal separator & vertical separator

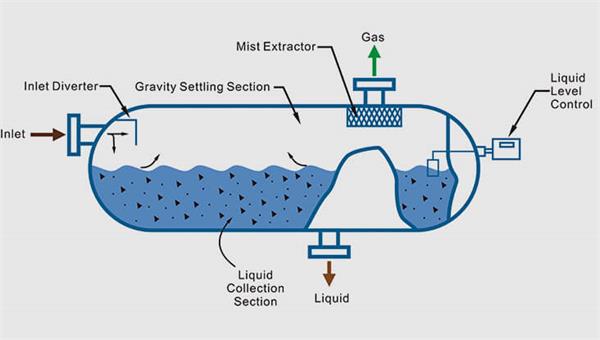

Separators used in oilfields can be divided into horizontal separators and vertical separators according to theinstallation methods. According to its performance, it can also be divided into test separator, production separator, oil-gastwo-phase separator and oil-gas-water three-phase separator.

Generally, horizontal separator is the popular choice for customers due to its wide range of applications, low unit processing cost, easy for installation, operationand maintenance. Furthermore, with its large gas-liquid interface area, bubbles in crude oil are easy to rise to gas-phase space. Therefore, it has perfect gas-liquid separation effect which can meet customer requirements.

In order to make you understand more intuitively, we made a comparison between horizontal separator and vertical separator. Please check the table below:

| Type | Vertical | Horizontal |

| Advantages | l Easy to clean l Less occupied area l Sensitive level controlling lLarge space for gas-liquid separation | l Small diameter l Large gas-liquid interface&perfect separation effect l Skid-mountable design, easy to install&transport l Low cost |

Disadvantages | l Large separatordiameter l High cost l Inconvenient to transport | l Difficult to clean (the separator is not suitable for sand-containing conditions) l High requirement forlevel control l Large occupied area & inconvenient high level erection |

Best Choice | mostly used in occasions where the volume of separating liquid is small and the space of separating gas and liquid is large, such as gas buffer tank, etc. | often used to separate gas-liquid separation processes with large amount of liquids and a small amount of water in liquids, such as reflux tanks. |

Through the above comparison, you can make appropriate choices according to your own working conditions.