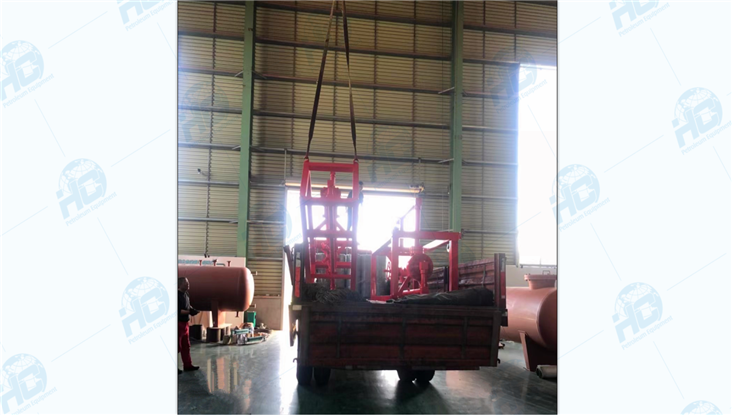

Two cyclone desanders were successfully sent to Tianjin, China

Two cyclone desanders ordered by Tianjin customers have been manufactured and sent out successfully. HC cyclone desander is made according to the screening principle of solid particles in the fluid rotating in the desander. It integrates cyclone and filtration, and can achieve remarkable effects of sand removal, turbidity reduction, solid-liquid separation and so on in the petrochemical field.

The working principle of the cyclone desander is based on centrifugal settlement and density difference. When the water flow enters the equipment tangentially from the desanding inlet under a certain pressure, it produces a strong rotational movement. Due to the difference of sand and water density, under the combined action of centrifugal force, centripetal force, buoyancy force and fluid traction force, the low-density water rises and is discharged from the water outlet, and the sand with high density is discharged from the drainage at the bottom of the equipment, so as to achieve the purpose of sand removal.

HC cyclone desander has the advantages of simple structure, convenient operation, safe and reliable use, less maintenance, small volume, large processing capacity, and less occupied area. It can remove sand particles in oil during the continuous oil supply process. We can not only produce cyclone desander, but also provide high-pressure desander with sulfur and acid resistance. HC supplies three-phase separator, desander, buffer tank, heat exchanger, water bath heater and other equipment for the oil and gas industry. We take "Embrace the infinite future" as our core philosophy, and strive to build a corporate vision of the most trustworthy and respectable oil and gas well surface testing equipment manufacturer in China, so as to create value and profits for customers.