3-phase Vertical Separator & Choke Manifold Ordered by Thai Customer

Recently, HC signed an order agreement for three-phase vertical separator and choke manifold with Thailand customer, with an agreed delivery period of 2 to 3 months, and the technical drawings are being confirmed.

Technical parameters of vertical separator:

Dimension: 48" x 12'-10" (S/S)

Design pressure: 285psig

Working temperature: 20-100F

Design temperature: 100F

According to customer requirements, the equipment is designed in accordance with ASMEVIII Div.1, and is equipped with ball valve, check valve, regulating valve, safety valve, flowmeter, level gauge, controller, level switch and other valve instruments.

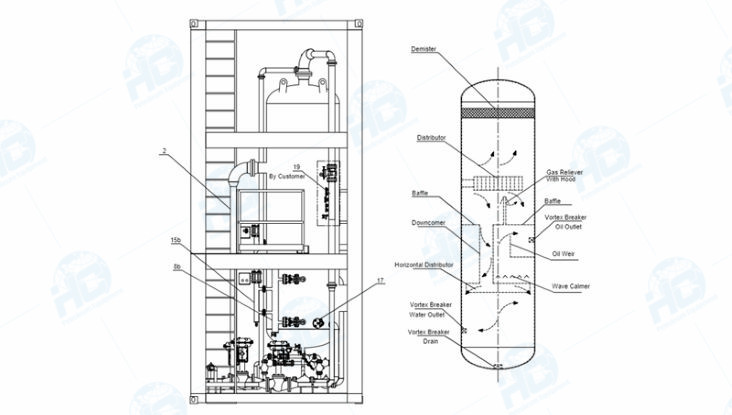

The vertical three-phase separator is generally used to process crude oil with low gas-oil ratio or very high oil-gas ratio, and is with less occupied area and easy-to-control level. The principle is that after the gas mixed fluid enters the separator through the gas-liquid inlet, the separation of the basic phase is completed through the sudden change of flow rate and flow direction; The gas flows upward in the gas channel and separates the droplets by gravity sedimentation; The liquid enters the oil-water interface through the downcomer; The bubbles and oil flow upward, and the water flows downward to separate; Before leaving the separator, the gas flows out of the outlet after removing small droplets through the mist collector; The oil enters the oil tank from the top through the overflow baffle and flows out of the oil outlet, and the water flows out of the water outlet.

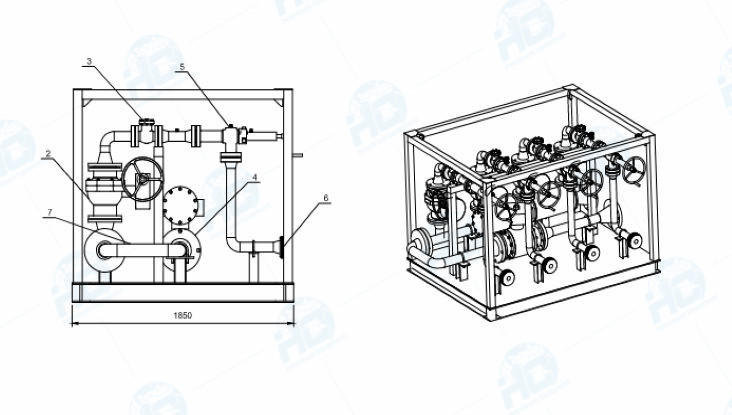

Choke manifold is an assembly composed of high-pressure valve and choke, which is used to reduce wellhead pressure, and it operates by opening and closing adjustable or fixed chokes. The choke manifold produced by HC is with strong corrosion resistance and high safety, which includes choke valve, pneumatic ball valve, check valve and other accessories, and with DNV structured skid.