Five Processes for Crude Oil Treatment

Crude oil generally contains salt and water, which can cause corrosion of equipment. Therefore, before entering atmospheric vacuum pressure, crude oil should be desalinated and dehydratedfirst. In addition, a large amount of gas will be generated during the heating of the crude oil. And explosion accidents will occur if it is not treated in time. Therefore, crude oil must go through the following processesbefore it becomes transportable oil:

1)Dehydration of crude oil: Thecrude oil extracted from wells generally contains a certain amount of water, and excessive water content in crude oil will cause waste in storage and transportation and increase energy consumption of equipment; most of the water in crude oil contains salts, which accelerates corrosion of equipment, containers and pipelines; in the process of petroleum refining, when water and crude oil are heated together, water will rapidly vaporize and expand, which will affect the normal operation of the refinery and the quality of the product, and even cause explosions. Therefore, dehydration is necessary before crude oil is transported.

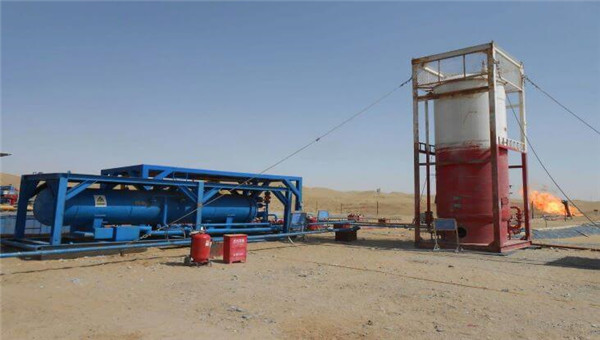

2)Degassing of crude oil: The process of separating gaseous light hydrocarbon components from crude oil through oil-gas separator and crude oil stabilizer is called degassing of crude oil.

3)Gas-liquid separation: When oil in formation reaches the wellhead of oil and gas wellhead and then flows along the oil or gas production pipeline, it often forms gas-liquid phase with the change of pressure and temperature conditions. In order to meet the needs of oil and gas wellproduct metering, mine processing, storage and transportation, it is necessary to separate the formed gas-liquid phases and transport them by different pipelines, which is called physical or mechanical separation.

4)Oil and gas metering: Oil and gas metering refers to the measurement of oil and natural gas flows. It is mainly divided into two types: oil well production metering and external flow metering. Oil well production metering refers to the determination of oil production and gas production of a single well. It is the key data for oil well management and reservoir performance control. External flow metering is the measurement of oil and natural gas transmission flow. It is the basic basis for oil and gas transfer management between the exporter and the receiver.

5)Oil and gas storage and transportation: The storage and transportation of oil and natural gas mainly refers to the process of delivering qualified crude oil, natural gas and other products from oil depots, transfer terminals or outbound first stations in oil and gas fields to refineries, petrochemical plants and other users through long distance oil and gas pipelines, oil tank trains or tankers.