Understanding the Working Principle of Three-Phase Oil and Water Separators

A three-phase oil and water separation refers to the process of separating a mixture of oil, water, and gas into three distinct phases: oil, water, and gas. This separation process is commonly used in the oil and gas industry to extract and process crude oil and natural gas.

Here's how the three-phase oil and water separation process typically works:

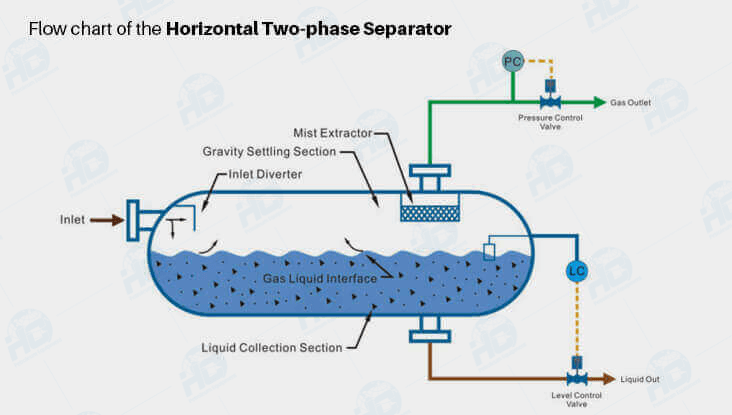

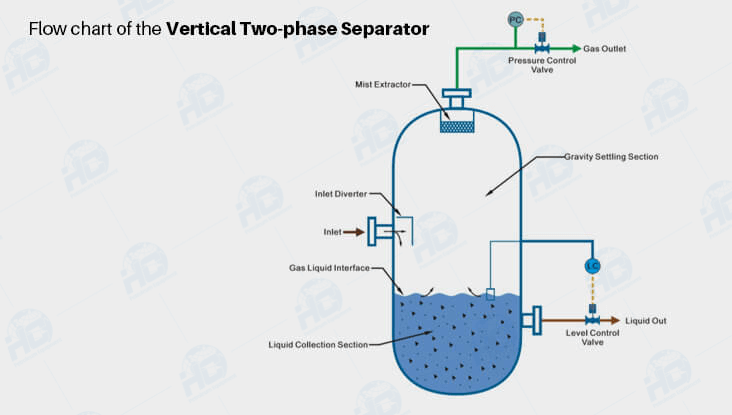

Inlet: The mixture of oil, water, and gas is introduced into the separation vessel or tank through an inlet.

Primary Separation: Once inside the vessel, the mixture undergoes primary separation based on the density differences between oil, water, and gas. Due to these differences, the components of the mixture stratify, with gas rising to the top, oil settling in the middle, and water collecting at the bottom.

Separation Stage: The separation vessel often includes internal devices such as baffles or coalescers to enhance the separation process. These devices help create turbulence or swirling motion within the vessel, facilitating faster and more efficient separation of oil, water, and gas.

Collection: Once the separation is complete, each phase is collected from its respective layer within the vessel. Gas is typically removed from the top, oil is withdrawn from the middle layer, and water is drained from the bottom. Each phase is then directed to further processing or storage facilities through separate pipelines.

Control: Three-phase separators are equipped with control devices such as level controllers and pressure controllers to maintain safe operating conditions within the vessel.

In summary, a three-phase oil and water separation process utilizes the density differences between oil, water, and gas, along with gravity, to separate the components effectively. Proper vessel design and control mechanisms ensure efficient separation and the collection of each phase for further processing.

Are the working principles of horizontal and vertical three-phase separators the same?

The working principles of horizontal three-phase separators and vertical three-phase separators are basically the same. They are both devices used to separate oil, gas, and water. The main difference between them lies in their structure, appearance, and the scenarios they are applicable to.

In terms of working principles, whether horizontal or vertical, three-phase separators utilize the density differences between oil, gas, and water, as well as gravity, to achieve separation. After the mixture enters the separator and undergoes stratification, oil, gas, and water are respectively located in different layers, and then collected and discharged through corresponding outlets.

Horizontal three-phase separators are usually more suitable for situations with larger site areas because they occupy more space horizontally. Vertical three-phase separators, on the other hand, are more suitable for situations with limited space since they occupy less space vertically. When choosing which type of separator to use, specific site conditions and processing requirements need to be considered.