The Heating Principle of Oilfield Water Bath Heaters

Water bath heaters are essential components in the oil and gas industry, primarily used for heating natural gas and oil. They play a crucial role in maintaining optimal temperatures for various processes, such as gas processing, oil refining, and petrochemical production. This unassuming apparatus stands as a sentinel, guarding against the chilling embrace of frigid temperatures that seek to impede the flow of natural gas and oil.

Working Principle of Water Bath Heaters

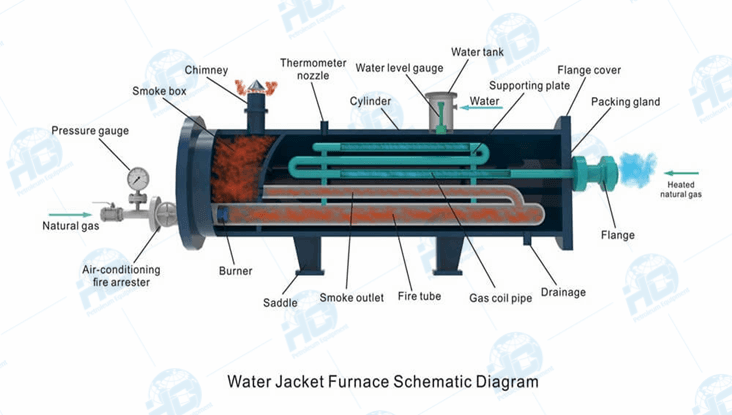

Water bath heaters operate on a simple yet effective principle. The heater consists of a large, insulated vessel filled with water, which acts as a heating medium. A coil or tube bundle is submerged in the water, carrying the fluid to be heated, such as natural gas or oil. The burner fires into a combustion chamber, heating the water and creating a thermal gradient. As the fluid flows through the coil or tube bundle, it absorbs heat from the hot water, raising its temperature to the desired level.

Key Components of Water Bath Heaters

Burner Assembly: The burner provides the heat source for the water bath heater. It is designed to efficiently combust fuel, such as natural gas or propane, and transfer the heat to the water bath.

Water Bath: The water bath serves as the heat transfer medium. It surrounds the coil or tube bundle, ensuring uniform heating of the fluid passing through it.

Coil or Tube Bundle: This component carries the fluid to be heated. It is submerged in the water bath, allowing for efficient heat transfer from the hot water to the fluid.

Insulation: Insulation is essential to minimize heat loss from the water bath heater. It helps maintain a stable temperature within the heater, improving efficiency.

Temperature Controls: Temperature sensors and controls are used to monitor and maintain the desired temperature of the fluid leaving the heater. This ensures consistent heating performance and prevents overheating.

Applications in the Oilfield

Water bath heaters are widely used in the oilfield for various applications, including:

Heating Crude Oil: Water bath heaters are used to heat crude oil before it enters the refining process. Heating reduces the viscosity of the oil, making it easier to transport and process.

Gas Processing: In natural gas processing plants, water bath heaters are used to heat natural gas streams to prevent the formation of hydrates and ensure smooth processing.

Hydrate Prevention: Water bath heaters are also used in pipelines to prevent the formation of hydrates, which can cause blockages and damage equipment.

Equipment Heating: Water bath heaters are used to preheat equipment such as pumps and valves, ensuring they operate efficiently in cold environments.

Water bath heaters are essential components in the oil and gas industry, providing efficient and reliable heating for various processes. Their simple yet effective design, coupled with their versatility and reliability, makes them indispensable in the oilfield.