One Minute to Understand How to Reduce Oil and Gas Separation Costs

In today's volatile energy market, oil and gas field developers are under immense pressure to optimize their operations and reduce costs without compromising efficiency. As the demand for energy continues to rise, the challenge lies in balancing operational efficiency with cost-effectiveness, particularly in the crucial process of oil and gas separation. This process, essential for ensuring the purity and quality of extracted resources, requires advanced equipment that not only performs effectively but also operates economically.

The Core Challenge: Balancing Efficiency and Cost

For oil and gas field developers, the separation of oil, gas, and water is a fundamental step in production. However, traditional separation equipment often comes with high operating costs, frequent maintenance needs, and energy inefficiencies. These factors contribute to increased operational expenses and reduced profitability. The question then becomes: How can developers maintain high separation efficiency while simultaneously reducing costs?

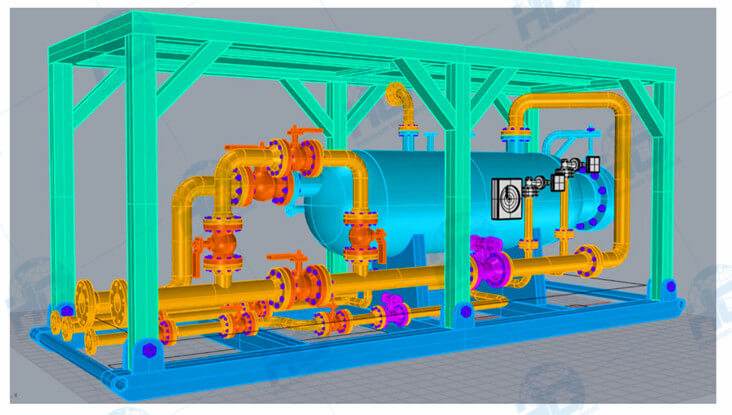

As a leading petrochemical equipment manufacturer, HC offers advanced three-phase separators designed to tackle these challenges head-on. Our separators are engineered with cutting-edge technology to ensure maximum separation efficiency while minimizing energy consumption and maintenance costs.

High Efficiency, Low Operating Costs: HC’s three-phase separators are built to deliver superior separation efficiency. Our innovative designs ensure that oil, gas, and water are separated with precision, reducing the need for reprocessing and minimizing wastage. This efficiency translates directly into cost savings, as less energy is required to achieve optimal separation.

Robust and Reliable: Durability and reliability are at the core of HC’s product design. Our separators are constructed using high-quality materials that withstand harsh operational environments, leading to fewer breakdowns and lower maintenance costs. This reliability ensures continuous operation, reducing the risk of costly downtime.

Environmentally Friendly Solutions: In an era where environmental compliance is critical, HC’s separators are designed to meet stringent environmental standards. By reducing emissions and ensuring cleaner operations, our equipment helps developers avoid regulatory fines and enhances their sustainability profile.

Customizable Designs: Understanding that every oil and gas field has unique needs, HC offers customizable separator solutions. Our team of experts works closely with clients to tailor our products to meet specific operational requirements, ensuring optimal performance in any given environment.

Expert Support and Service: We believe in providing comprehensive support throughout the equipment's lifecycle. From installation to regular maintenance and troubleshooting, our team of experts is always on hand to ensure that your operations run smoothly and efficiently.

In a market where every dollar counts, HC’s three-phase separators offer oil and gas developers the perfect balance of efficiency and cost-effectiveness. By investing in our advanced separation technology, developers can significantly reduce operational costs, improve resource recovery, and ensure compliance with environmental regulations. When it comes to optimizing oil and gas separation, HC is the partner you can trust to deliver superior results with lasting value.