How to Customize Separators for High-Water-Cut Oilfields

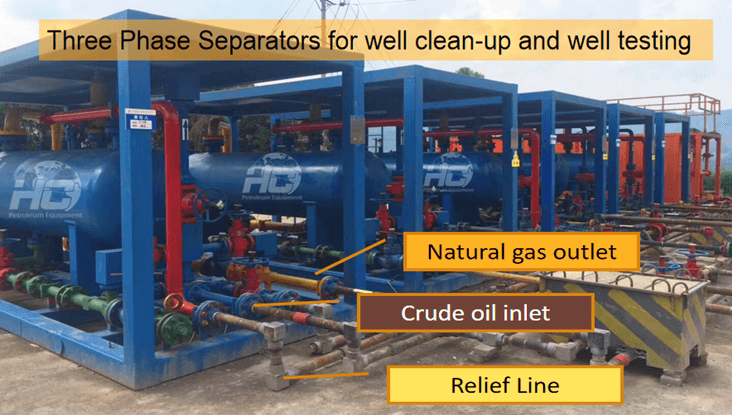

High-water-cut oilfields, where the produced fluid contains a significant amount of water, present unique challenges for oil and gas separation. As production continues, water content in crude oil increases, leading to reduced separation efficiency, accelerated equipment corrosion, higher water treatment demands, and increased processing capacity requirements. To address these challenges, HC provides customized three-phase separators designed specifically for high-water-cut conditions, ensuring efficient separation, enhanced durability, and operational stability.

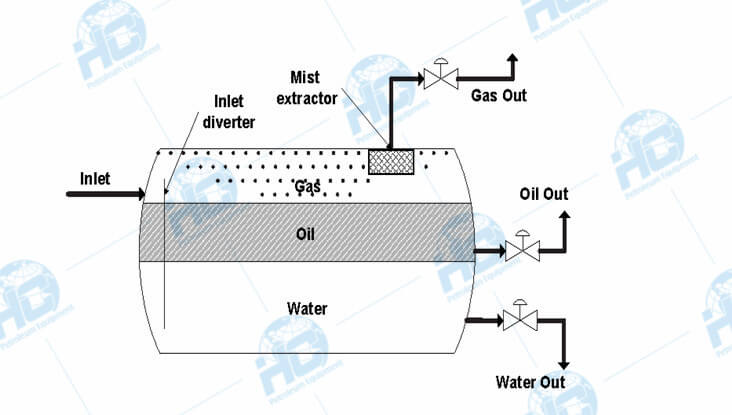

To improve separation efficiency, HC optimizes internal components, incorporating specialized baffle structures, cyclones, and high-performance packing to accelerate oil-water stratification. The use of precise liquid level control systems stabilizes the oil-water interface, reducing oil content in separated water, while demulsification units effectively break emulsions that commonly occur in high-water-cut environments. Moreover, since excessive water content exacerbates corrosion, HC selects corrosion-resistant materials such as stainless steel, nickel alloys, and anti-corrosion coatings, with additional options like internal rubber linings or epoxy coatings to prolong service life.

Beyond structural improvements, HC integrates intelligent automation into separator design, equipping units with automated liquid level control to minimize manual intervention and enhance operational accuracy. A real-time data monitoring system ensures precise control over separation performance, optimizing drainage management to meet production requirements. Additionally, to accommodate different oilfield conditions, HC offers customized designs, including horizontal or vertical separators, multi-stage separation systems for high-flow-rate wells, and heating functions such as built-in heating coils to reduce viscosity and enhance separation.

In high-water-cut oilfields, effective separation often requires supporting equipment such as water bath heaters (WBH) and surge tanks. Water bath heaters play a crucial role in maintaining optimal crude oil temperature, reducing viscosity, and enhancing phase separation efficiency, especially in cold environments or heavy oil fields. surge tanks, on the other hand, help stabilize fluid flow, ensuring smoother operation of separation systems while preventing pressure fluctuations. By integrating these auxiliary systems with our high-efficiency three-phase separators, HC provides a complete crude oil processing equipment solution, ensuring stable production and minimizing operational risks.

HC’s advanced three-phase separators provide superior oil-water separation efficiency, exceptional corrosion resistance, intelligent operation, and tailored configurations to meet the demands of high-water-cut oilfields. With extensive engineering expertise and adherence to stringent manufacturing standards, HC delivers cost-effective and high-performance separation solutions, ensuring that oilfield operators can efficiently manage water-heavy crude production while minimizing operational risks and maintenance costs. If your oilfield requires an optimized separation solution, HC is ready to provide a customized system to enhance production efficiency and long-term reliability.