How to Select the Size of a Three-Phase Separator Based on Gas-to-Liquid Ratio

In oil and gas processing, sizing a three-phase separator is often a balancing act between performance, cost, and operational stability. Among all the parameters involved, the gas-to-liquid ratio (GLR) is one that tends to be underestimated, yet it’s usually the very first factor that should be considered.

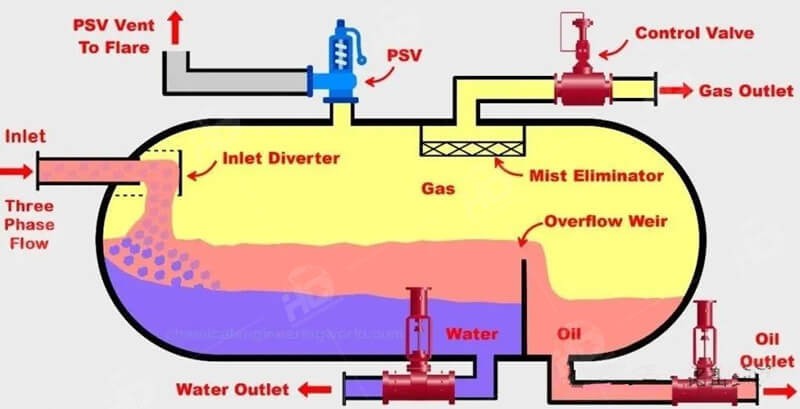

Simply put, the gas-to-liquid ratio is the proportion of gas volume to liquid volume under the same flow conditions. When the gas fraction is high, the flow velocity in the pipeline increases, making it easier for liquid droplets to be carried over with the gas. In such cases, the separator needs enough disengagement space to allow those droplets to settle out. When the liquid fraction dominates, gas handling is less of an issue, but the liquid requires adequate retention time to complete separation, which means the vessel’s liquid section has to be larger. Ignoring GLR often leads to problems like gas carry-under or liquid carry-over — both of which can cause trouble for downstream compressors or pumps.

GLR, however, is not the only player in this game. Pressure and temperature also have a direct impact. Higher pressure increases gas density, allowing more gas to occupy the same volume, which changes the vessel diameter calculation. Higher temperature, on the other hand, lowers density and can increase the volume requirement. The properties of the fluids themselves matter too. For instance, if the liquid has high viscosity, droplets will settle more slowly, and even with a reasonable GLR, you might still need a larger separation space.

In engineering practice, we typically start by calculating the gas section diameter from the stabilized gas flow rate, corrected for density and viscosity based on operating pressure and temperature. Then, we determine the liquid hold-up volume needed for the required retention time. The larger of these two values becomes the basis for sizing, after which we add a design margin — often 10% to 20% — to account for future production fluctuations.

Experience has shown that even with the same GLR, fluids from different fields can behave very differently in operation. That’s why sizing isn’t just about applying a formula. Field data, process variability, and fluid properties all need to be part of the equation. At HC, we often adjust our calculated results based on years of operational experience, ensuring that the separator is both economical and reliable in real-world conditions.