Enhancing Sand Management in Oilfields: The Role of Cyclone Desanders in Reliable Production

In oil and gas fields, sand production remains one of the most persistent operational challenges. Even small amounts of sand can lead to serious issues such as erosion of pipelines, valve damage, separator malfunction, and unexpected downtime. These problems not only compromise safety but also increase OPEX by requiring frequent maintenance and component replacement.

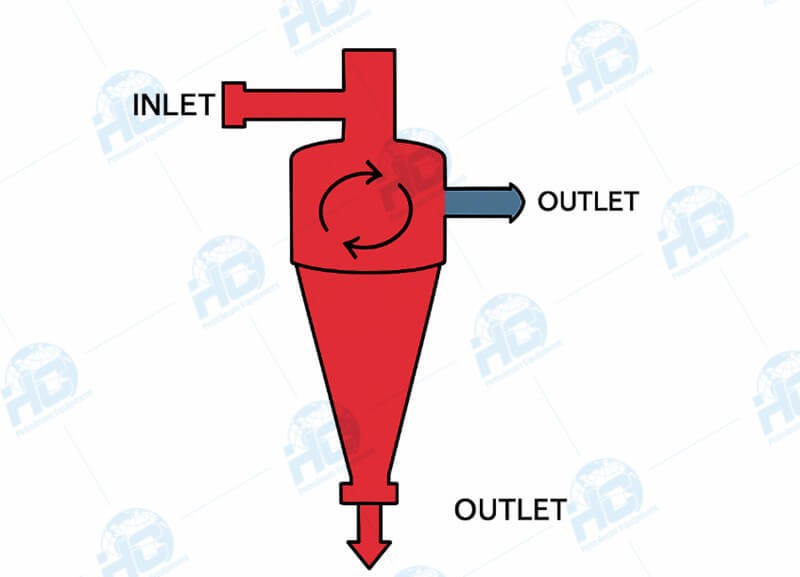

Cyclone desanders, also known as hydrocyclones, provide a proven solution for managing sand effectively at the wellhead and early processing stages. By using centrifugal force, cyclone desanders separate sand particles from the production stream with high efficiency, ensuring that clean fluids continue downstream while solids are discharged safely.

At HC, our desander systems are engineered for demanding oilfield environments, including high-pressure and high-temperature (HPHT) conditions. With a compact footprint and no moving parts, they offer several advantages:

Reduced erosion risks: Protecting pipelines, valves, and separators from sand abrasion.

Lower OPEX: Extending equipment lifespan and minimizing unplanned interventions.

Operational reliability: Maintaining stable flow conditions and reducing downtime.

Flexible integration: Skid-mounted or trailer-mounted options for onshore and offshore applications.

For operators facing challenges such as frequent shutdowns, equipment wear, or declining production efficiency due to sand, cyclone desanders are not just optional—they are essential. They play a key role in modern sand management strategies, ensuring both production continuity and asset integrity.

HC has successfully delivered desander systems to oilfields across Asia, the Middle East, and Africa, supporting clients in achieving safer, more reliable, and cost-effective production.