Early Production Facility Solutions Built on Practical Engineering Experience

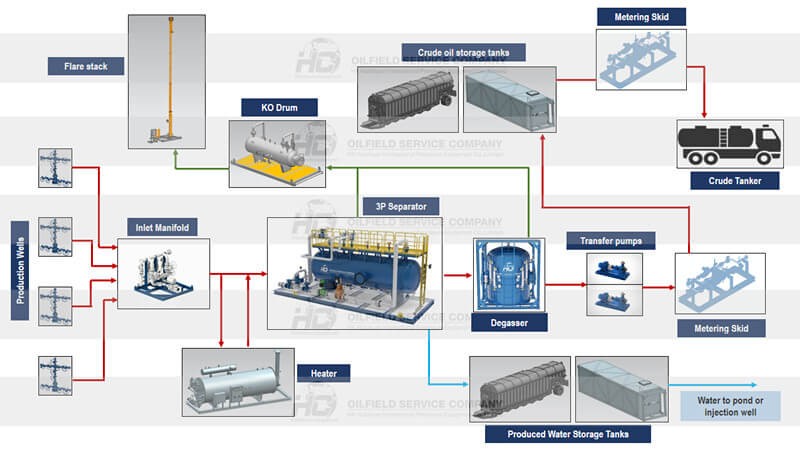

When operators talk about an early production facility, they are usually not looking for a complex processing plant. What they need is a system that can be put into operation quickly, works reliably from day one, and continues to perform even when well conditions are still changing.

In many early-stage fields, production data is incomplete, flow rates fluctuate, and the gas–liquid ratio is far from stable. Sand production, water cut and seasonal temperature changes often appear later than expected. This is why an early production facility has to be designed with enough flexibility, rather than built around a fixed set of assumptions.

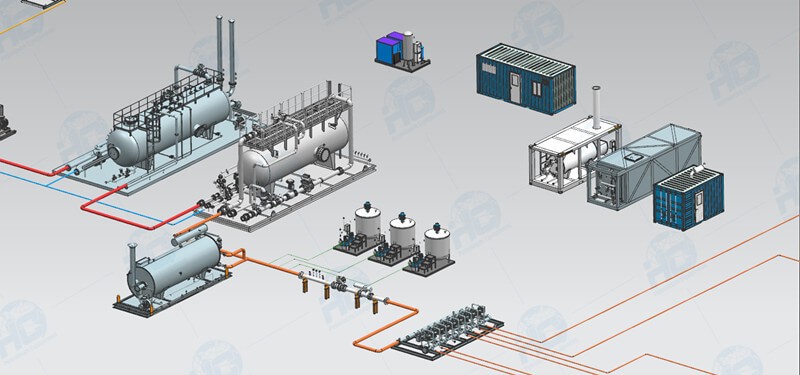

At HC, early production facilities are treated as working production systems, not demonstration units. In practice, this means paying more attention to how equipment behaves on site than how it looks on paper. Separators, heaters, heat exchangers, surge tanks and desanders are selected and sized based on how they will operate together once the wells are connected.

Separator performance is often the first concern. In early production, a three-phase separator may operate far below its design capacity for long periods, then suddenly see higher liquid or gas rates. If the separator is sized only for peak flow, separation efficiency can suffer during low-rate operation. For this reason, HC focuses on stable separation across a wide operating range, ensuring that oil, gas and water separation remains consistent even when production is uneven.

Temperature control is another common challenge, especially in colder regions or during winter operation. Water Bath Heaters are frequently used in early production facilities to prevent hydrate formation and keep the process stable. Rather than maximizing heating power, the key is matching the heater capacity to actual field conditions, fuel availability and operating patterns. Overheating wastes fuel and increases maintenance, while insufficient heating leads to operational risks.

As production continues, sand and solids often become more noticeable. Desanders and surge tanks are introduced not as optional accessories, but as protective equipment that extends the service life of downstream systems. In many projects, these units reduce unexpected shutdowns and simplify daily operation for site personnel.

From an engineering perspective, compliance with international standards is only part of the picture. More important is how the equipment is fabricated, inspected and tested before delivery. Early production facilities are often installed in remote locations where repair resources are limited. Reliable fabrication quality and practical design details make a real difference once the system is running.

Over the years, HC has supplied equipment for early production facilities in a variety of operating environments. Feedback from field operations consistently shows that simple, well-engineered solutions perform better than overly complicated systems during early production stages. This experience continues to shape how we design and deliver EPF equipment today.