What is the internal structure and function of the oil and gas separator?

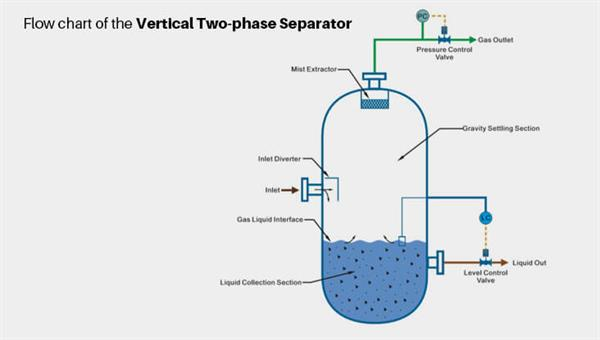

Oil/gas separator is a device that separates the gas/liquid or oil/gas/water in the mixture of oil & gas wells. Its overall structure can be horizontal, vertical or spherical.

Oil/gas separator is generally composed of primary separation zone, gas zone, liquid zone, demisting zone and oil gathering zone.

The function of primary separation zone is to separate the gas/liquid mixture to obtain the liquid flow and gas flow. The inlet guide element and buffer element are usually set in this zone to reduce the oil/gas flow rate, disperse the gas/liquid flow, reduce the oil/gas carrying, and create conditions for the next section separation.

The function of gas zone is to perform gravity sedimentation and separation of large droplets carried in the gas flow. In order to improve the separation effect of droplets, rectifier element is usually provided in the gas zone.

The function of liquid zone is mainly to separate the free gas carried in the liquid flow in two-phase separator. In order to have better separation effect, the design of liquid zone must ensure that the liquid has sufficient residence time. In the three-phase separator, apart from separating free gas, the liquid zone also has the function of separating oil from free water. To improve the effect of oil/water separation, coalescence element is usually installed in the liquid zone.

The function of demisting zone is to further separate the droplets carried in the gas flow. The zone is equipped with demisting elements to capture the droplets in the gas flow by means of collision separation principle.

The function of oil gathering zone is to store part of the oil and maintain a stable production level.

Different types of separation devices will be used in different projects, but no matter which one is selected, factors such as impurity composition carried by oil & gas well mixture, stability of conveying pressure and flow, fluctuation range, etc. shall be considered. On the premise of satisfying the requirements of output quality, it is necessary to strive for reliable structure and excellent separation effect without frequent replacement and cleaning of components.

.jpg)

Based on the above considerations, the three-phase separator and two-phase separator produced by HC Petroleum Equipment adopt the advanced technology of effective separation, throttling, automatic control, comprehensive anti-corrosion and skid-mounted structure, which is convenient to operate and stable in performance, and can not only save the operating cost of users but also ensure the safety of operators. Therefor, it is the best choice for users.

HC separation equipment is manufactured in full compliance with international standards and is ASME certified. Please do not hesitate if you have any requirements. Our engineering team will develop the most ideal solution for you with rich experience.