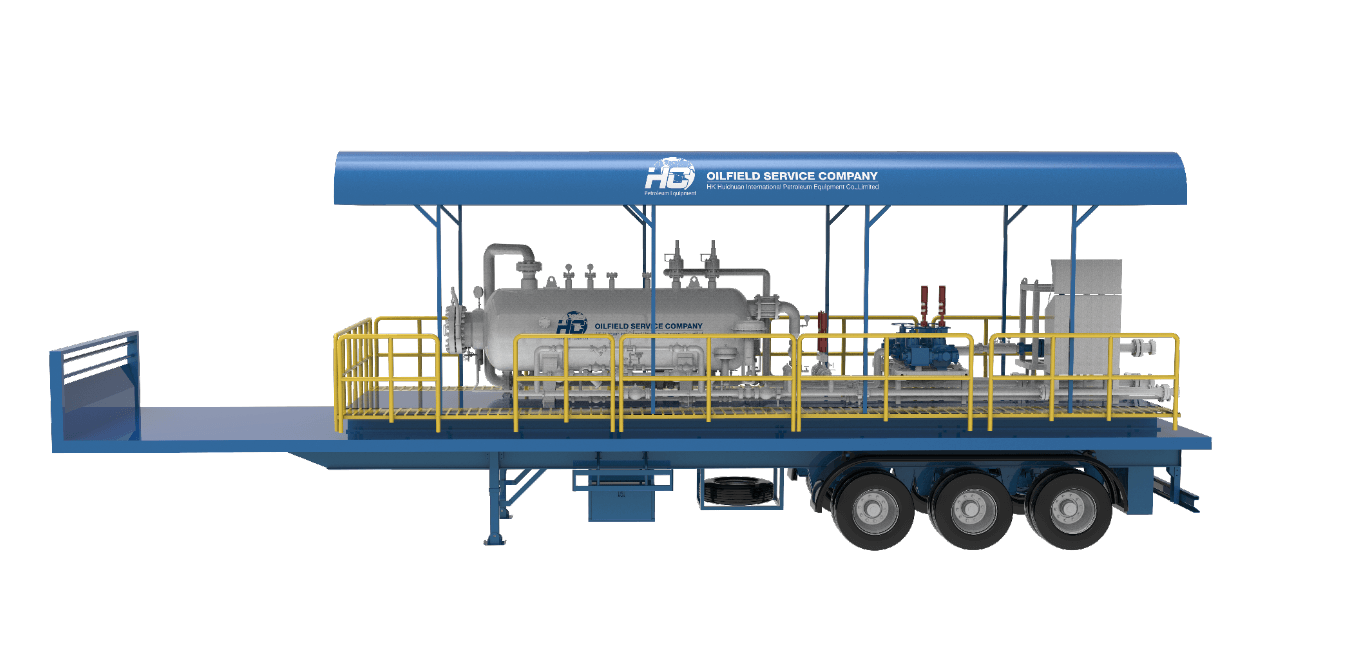

Mobile Test Separator with ESD and Choke Manifold

Current mobile separator with ESD and choke manifold allow fast mobility, safe and efficient well testing,Our trailer can be longer or shorter based on the client’s operational requirements.

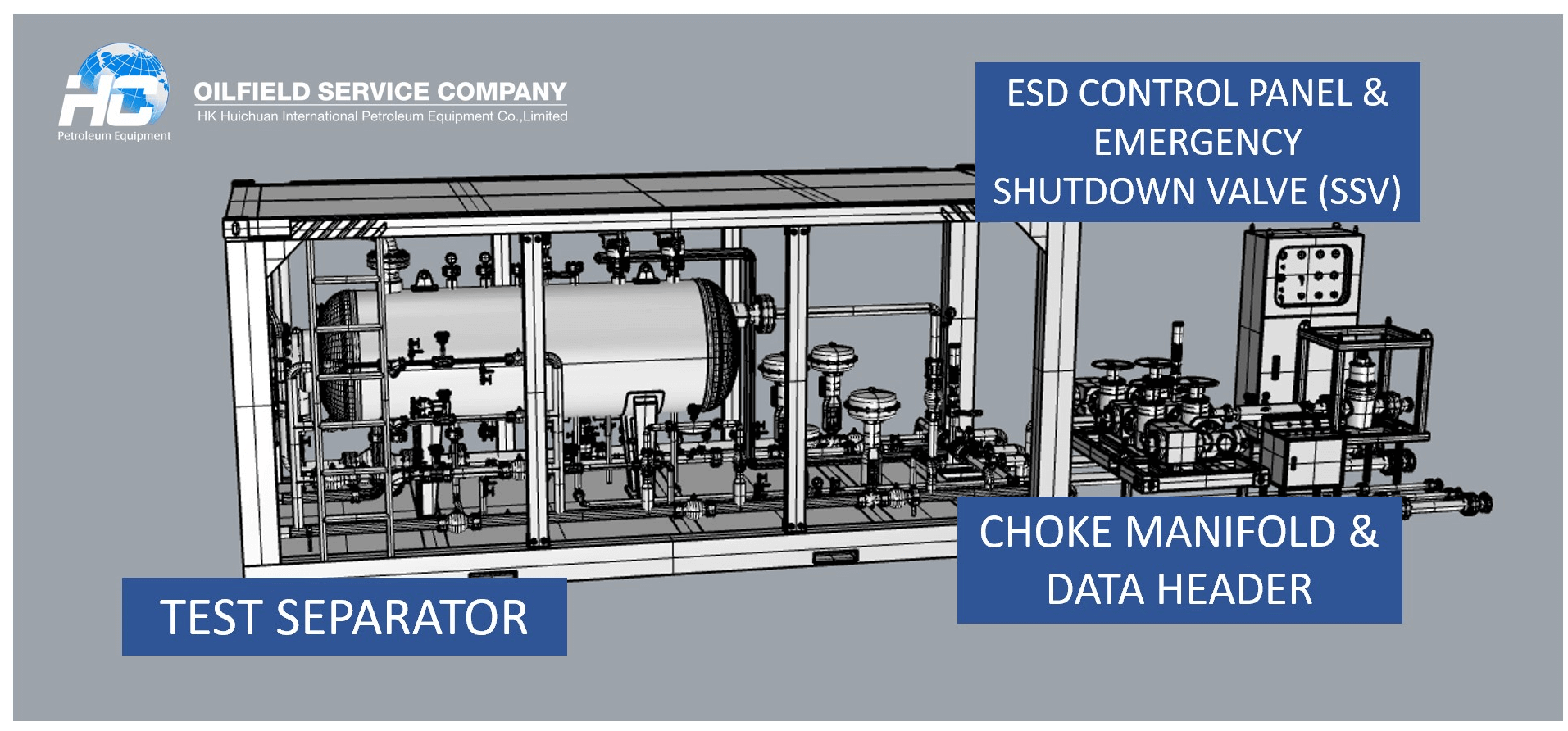

Current model of trailer-mounted packages is designed to accommodate conventional test separator, equipment of emergency shutdown system, choke manifold and data header. Current mobile separator with ESD and choke manifold allow fast mobility, safe and efficient well testing. As show in 3D modeling, current model requires lighter trailer base as HC considered light frame for test separator. Trailer can be longer or shorter based on the client’s operational requirements.

Surface well test trailer package (SWT Package) or trailer mounted surface well test system is a special system of well test equipment designed to separate well fluids into two/three/four phases, then accurately measure behavior of each phase after separations.

Test Separator Skid is in the center of any well testing operation. Test separator separates well fluids into two/three/four phases. Each phase line consists of control valves, meters, ball valves and other components specified in the technical proposal. As the safety devices, two or three relief valves are installed on the separator vessel and inlet manifold (Note: confirm with HC required quantity of relief valves and place of installation). High/Low- or High-Pressure Pilots are also can be used as additional safety measures (Note: confirm if pilots are included in the scope). Pressure Vessel is made either made of standard service or sour services construction steel depending on the client’s requirements. Pressure Vessel has multiple nozzles to connect level gauges, level controllers, pressure and temperature gauges, instruments and other parts specified in technical proposal and P&ID.

Emergency Shutdown System (ESD System) consists of multiple equipment and parts are important parts of safety measures during well testing and production. ESD system consists of ESD control panel, 5K/10K/15K Surface Safety Valve (SSV), High/Low- or High-Pressure pilots, Pneumatic SS Pipes, hydraulic hoses, emergency pushbuttons. ESD Control Panel provides hydraulic pressure to actuators or SSV and SSV of Flowhead. ESD Control Panel is equipped with oil tank, pneumatic lines, pneumatic-hydraulic pump or hand pump, gauges and other parts which is specified in technical proposal.

_HC_Petroleum_Equipment_01.jpg)

5K/10K/15K Choke manifold is 4-valve or 5-valve assembly, which includes one positive and one adjustable choke. Choke Manifold is designed to reduce flow (pressure) of well stream, protecting downstream equipment.

Data Header is special pipe with unions and ports, designed to monitor pressure, temperature, and allow operator to inject chemical to the well fluids.

Test pump is designed to provide necessary pressure to the surface well test equipment before starting operation. Confirm with HC brand name or type of test pump required for your project.

Trailer base is designed to handle payload of 20/25/30 tons. For longer and heavier trailer mounted systems, please check the website of HC Petroleum Equipment.

Technical Parameters

Trailer length | 10-15 m. (32-50 feet) |

Trailer payload (no includes weight of trailer) | 25-60 tonnes |

Sets of hammer union | Yes |

Ex-proof LED lights | Yes |

Surface Shutdown Valve (SSV) | 2-4 in. 5000 – 150000 psi AA-EE, UL Hydraulic Actuator 2500-6500 psi SA36 / Q235 Skid |

Choke Manifold | 4-Valve, one positive choke, one fixed choke Sets of choke beans Multiple ports at entry and exit 2-4 in. 5000 – 150000 psi AA-EE, UL SA36 Skid SA36 / Q235 Skid |

ESD Control Panel | Pressure up to 6500 psi Pneumo-hydraulic pump or hand pump Sets of valves, instruments and regulators SS Oil tank with level gauge SS piping Multiple connection ports SS frame and skid |

Data Header | 2-4 in. 5000 – 150000 psi AA-EE, UL M/F union connection 3-6 connecting ports/nozzles Sets of chemical gauges |

Test Separator | Pressure Vessel Diam. 36-48 in. Pressure Vessel Length S/S – 10-15 ft. Pressure rating: 1440-2160 psi Design Code: ASME / GB150 Internals – Yes, SS for removable, CS for welded Gas Measurement: Orifice/Coriolis, Chart Recorder Liquid Measurement (Oil): Turbine/Coriolis, Analyzer/Transmitter, Shrinkage tester Liquid Measurement (Oil): Turbine, Analyzer/Transmitter. Level Controllers: Yes, Pneumatic Type. Fully digital is also available. Pressure Controllers: Yes, Pneumatic Type. Fully digital is also available. Sets of Manual Ball Valves: Yes Check Valves: Yes Strainer: TBD Needle Valves for instruments and sampling: Yes Thermowells: Yes Pressure and Temperature Gauges: Yes SS pneumatic piping: Yes Air Scrubber: Yes Relief Valves: Yes, either two on vessel or two and one on the vessel and inlet manifold Ex-proof Zone 1/2 LED lights and cables: Yes Quality outer coating: Yes Skid: Yes with lifting lungs and for forklift lifting |

Note: HC Petroleum Equipment can design and fabricate trailer-mounted equipment based on the client’s requirements, while serial models from own development is also available.

Note:

1. HC Petroleum Equipment can design and fabricate trailer-mounted equipment based on the client’s requirements, while serial models from own development is also available.

2. Please note that HC Petroleum Equipment can equip trailer mounted surface well test equipment with domestic brand valve and instruments, as well as world famous brand valve and instruments depending on your requirements. Please be specific about part brand names or ask HC for personal suggestion based on your requirements to the brand and performance.

HC Petroleum Equipment is a manufacturer and supplier of trailer-mounted packages in China. Please feel free to contact HC Petroleum Equipment for more technical information and price. We ensure that trailer-mounted equipment will be in compliance with international standards and meet your requirements to the quality and expectation to the price.