Fuel Gas Conditioning Unit

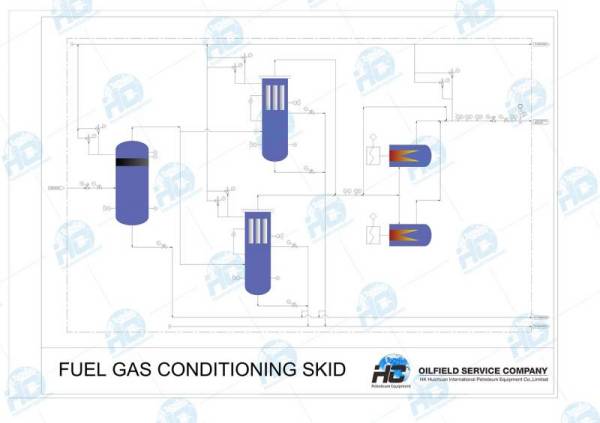

Fuel Gas Conditioning Unit is designed to treat (remove unwanted liquids and solids) the natural gas before delivering to the gas turbine.

Fuel Gas Conditioning Unit

Fuel Gas Conditioning Unit is designed to treat (remove unwanted liquids and solids) the natural gas before delivering to the gas turbine. Fuel Gas Conditioning Unit is also called Fuel Gas Conditioning System because it consists of several types of parts which performs various functions to achieve the required conditions of the natural gas for delivering to the gas turbine.

Typical Fuel Gas Conditioning System consist of:

Vertical Filter Separator

Filter Separator Internals (usually filter elements, coalescing pack)

Level gauges and transmitters

Pressure and temperature gauges

Differential Pressure gauges and transmitters

Control Valves

Relief/Safety Valves

Ball Valves or other types of open/close valves

Piping & Pipeline Accessories

Air-supply tubes and valves

Signal and power cables

Junction Boxes and Control Panel

Skid and frame

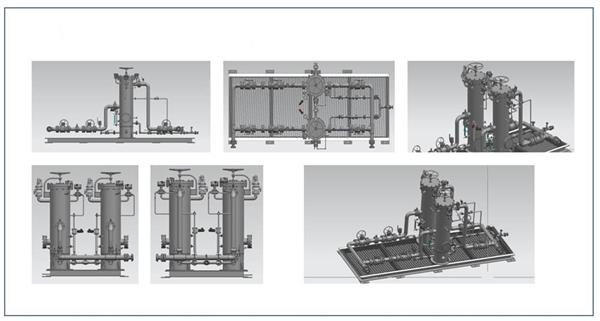

HC Petroleum Equipment designs, fabricates, supplies and provides commissioning services for various configuration of Fuel Gas Conditioning Units. Our In-house manufacturing and assembly facilities allow to deliver high-quality and cost-effective Fuel Gas Conditioning Systems within comparatively short period of time.

We perform our work strictly as per international and domestic standards, paying attention to each single detail and stages of work. Filter elements and coalescing packs are designed and supplied from experienced and certified vendors, while some of the complex custom-design packs are manufactured in-house. Valves and instruments are selected from proven-brand companies, which ensures the operability of the unit. Electrical parts are ex-proof and CE- and ATEX-certified. Signal Protocols are Foundation Fieldbus, HART or other.

| Flow Capacity | 2.5-221 (MMSCFD - Nm³/h) or client’s specific requirements |

| Pressure Rating | 400-1400 psi or client’s specific requirements |

| Filter Separator Sze | From 6.625 ×5.5 in. up to 42 x 12.5 in. From 168.28 ×1676.4 mm up to 1066.8 × 3810 mm or client’s specific requirements |

| Filtering Efficiency | 99-99.9 % |

| Working Medium | Natural Gas (Fuel Gas) with condensate, other liquids, particles (solids) |

| Construction Materials | Carbon Steel, Stainless Steel, Alloy Steel, Duplex |

| Code & Standards | ASME, ANSI, BS, EN, ISO, CE/PED, NACE, GOST, GB |

Typical Vertical Filter-Separator Vessel

Fuel Gas Conditioning 3D Modeling