Plug Catcher

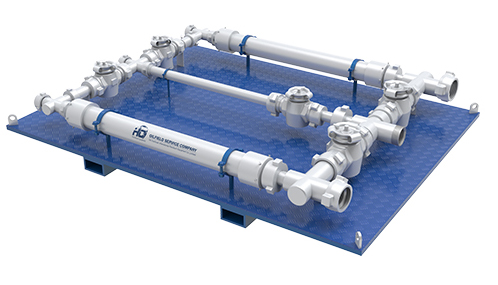

The plug catcher or junk catcher is a special mechanical piece of oilfield equipment designed to prevent downstream equipment from plugging and damage. Plug catchers consist of special cylinder with insert, gate or plug valves, integral fittings, hammer unions, which are installed in the skid.

The plug catcher or junk catcher is a special mechanical piece of oilfield equipment designed to prevent downstream equipment from plugging and damage. Plug catchers consist of special cylinder with insert, gate or plug valves, integral fittings, hammer unions, which are installed in the skid.

HC designs and fabricates single-barrel, dual-barrel, vertical and horizontal plug catchers for oilfield operations (flowback, surface well test, well clean-ups). Plug catchers designed by HC are easy to operate, safe, and mobile, providing perfect solution or oilfield service companies. HC also pays special attention to weight and effectiveness of the plug catcher’s structure, as additional weight increases both cost of product and transportation.

Our plug catchers are available in several sizes, pressure rating and service class. HC can design plug catchers both for standard and sour service. We use quality raw material which meets API standards handling high- and low-temperature applications.

Feel free to contact us for receiving technical assistance and quotation

Benefits

Self-contained skid

Fast delivery period

Quality performance

Safe operation

Durability

Features

Hydraulic Gate Valves

Plug Valves

Low-temperature application

Sour and standard service

Immediate technical assistance

Clear documentation and manuals

Pressure up to 15000 psi

Code & Standards

API 6A

ASME B31.3

NACE MR0175

CE/PED

DNV 2.7-1

Pressure Rating

5000 psi

10000 psi

15000 psi

Material Class

DD

EE