Steam Heat Exchanger

Steam heat exchanger is an unit of well testing package, which plays an important role to ensure well fluid reaches the necessary temperature level before entering the test separator.

Steam Heat Exchanger

Steam heat exchanger is an unit of well testing package, which plays an important role to ensure well fluid reaches the necessary temperature level before entering the test separator.

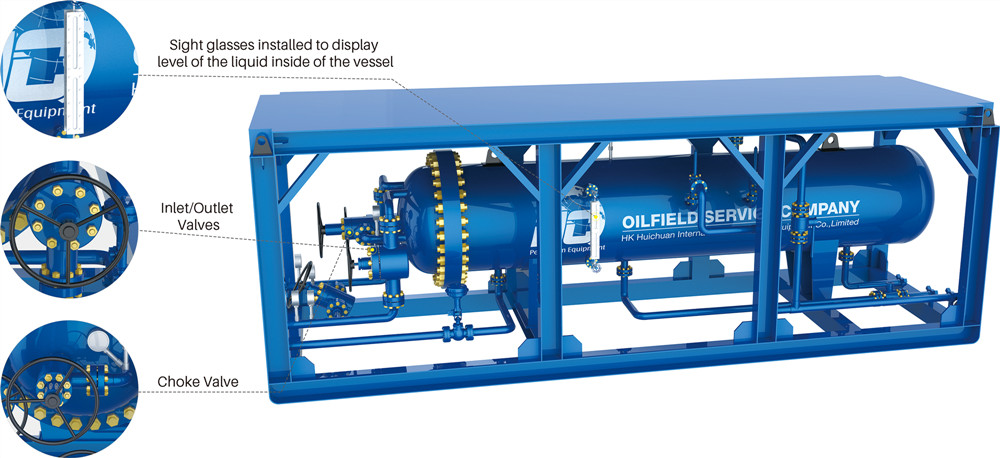

As steam heater transfers the heat from the steam to the well fluid, it can be considered as special type of heat exchangers, mostly used during well testing and well clean-ups. Configuration of the steam heat exchanger depends on the requirements of the oilfield service company or an operator, usually consists of flow-control valves, choke valve, level indicator, pressure and temperature gauges, safety valves and steam pressure controllers.

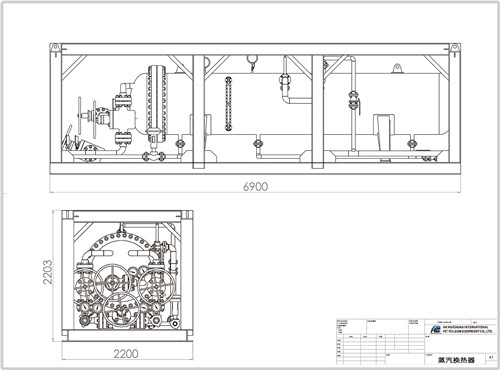

Technical Drawings

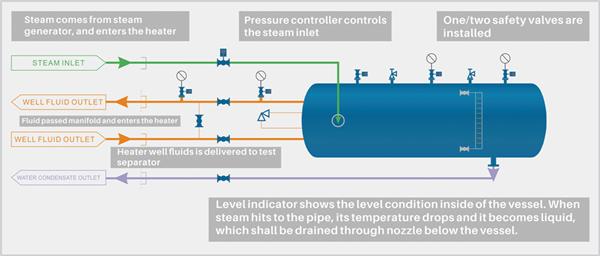

Working Process

Steam comes from a steam generator and enters the heater. Steam inlet pipeline is equipped with one or two pressure controllers to control steam flow. One or two safety valves are installed in case of pressure increase inside of the vessel. Level indicator shows the level condition inside of the vessel. When steam hits to the pipe, its temperature drops and it becomes liquid, which shall be drained through nozzle below the vessel.

Steam Heat Exchanger Serving As Well As Indirect Heater

Some manufacturers or the oilfield operators may order the steam heat exchanger with burner on the back, so they may switch to “indirect line heater” mode and/or “steam heat exchanger” mode. This kind of structure allows the oilfield services company to be flexible during the well testing in different areas, however, it shall fully comply with safety codes and norms of the region where equipment is operated. The most important is steam heater exchanger shall be safe for the personnel and facility.

Burner is installed on the back and chimney pipe on the top of the skid. It is installed upwards when equipment arrives well testing site.

| MODEL | HCSWE-15 | HCSWE-15 | HCSWE-11 | HCSWE-118 |

| SERVICE | sour | sour | sour | sour |

| SIZE | 42 in. x 15 ft. | 42 in. x 15 ft. | 48 in. x 18 ft. | 48 in. x 18 ft. |

| FlOW LINE PRESSURE | 5000 psig | 10000 psig | 10000 psig | 15000 psig |

| VESSEL PRESSURE | 250psi | 250psi | 250psi | 250psi |

| CHOKE SIZE | 3/4" | 3/4" | 3/4" | 3/4" |

| WELL FLUID INLET SIZE | 3/4" | 3/4" | 3/4" | 3/4" |

| WELL FLUID OUTLET SIZE | 3/4" | 3/4" | 3/4" | 3/4" |

| STEAM INLET/OUTLET SIZE | 2" | 2" | 2" | 2" |

| RELIEF SET PRESSURE | 3/4" | |||

| SKID DIMENSIONS | 20ft. x 6ft. x 8ft. | 20ft. x 6ft. x 8ft. | 20ft. x 6ft. x 8ft. | 20ft. x 6ft. x 8ft. |

| CODES & STANDARDS | NACE MR0175;API;ASME;ANSI;DNV(for offshore);ISO | |||