TEG (Glycol) Gas Dehydration

Glycol Dehydration is one of the gas dehydration processes, which applies absorption process by using liquid desiccant, triethylene glycol (TEG), to remove or lower water content from natural gas stream. There other liquid glycol-based desiccant, such as diethylene glycol (DEG), ethylene glycol (MEG), and tetraethylene glycol (TREG), while TEG remains one the most commonly applied liquid desiccant in gas treatment and processing industry. HC offers design, engineering and process calculation services for glycol gas dehydration systems.

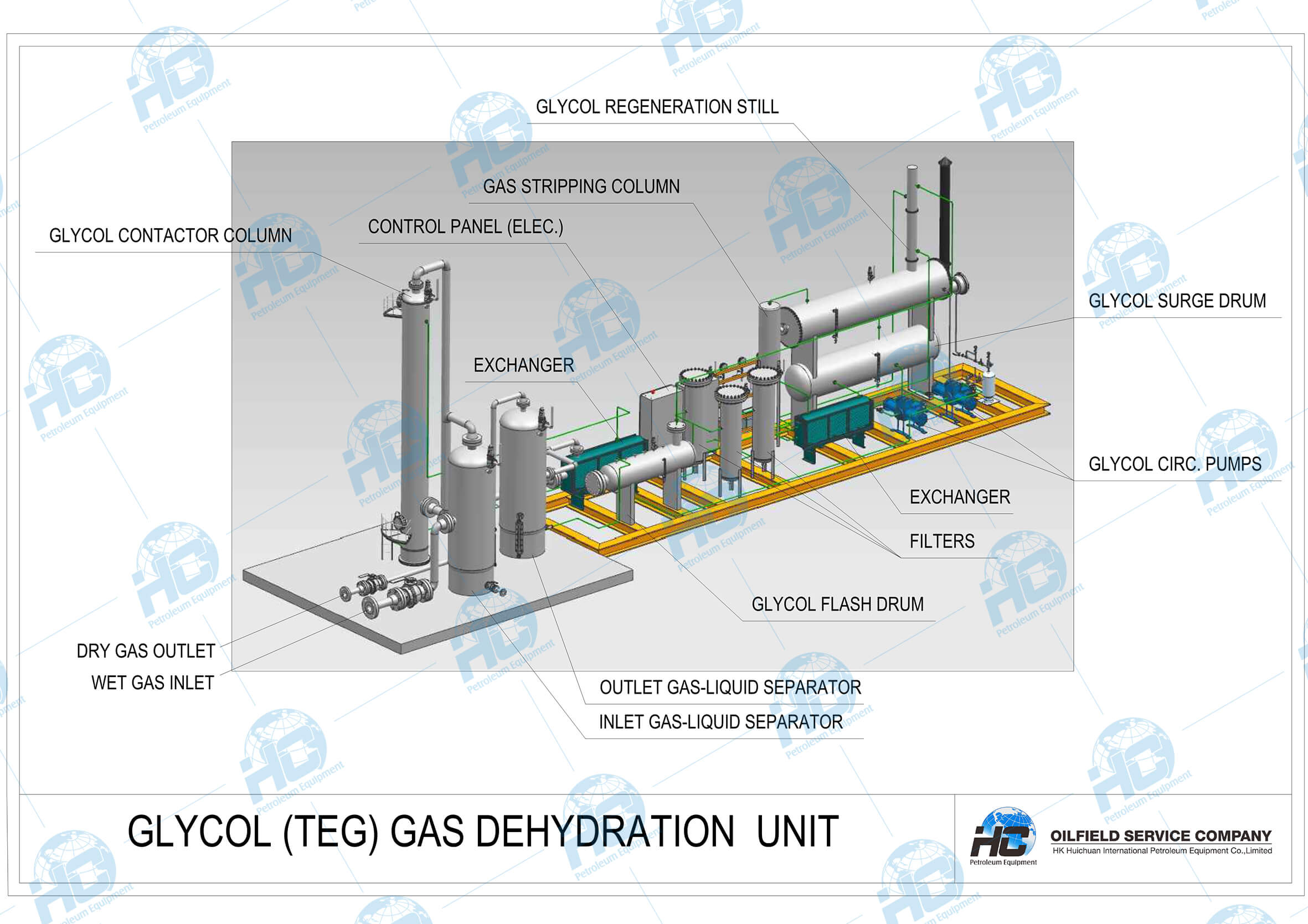

Special units or systems, known as TEG Gas Dehydration Units, allow applying glycol dehydration process to reach required outlet water content in export natural gas. There are several reasons for removing water from natural gas streams like to prevent corrosion as free water may certain portions of H2S or CO2, to prevent hydrate formation, dew point control, etc. TEG Gas Dehydration Units may vary in size based on the gas flow rate and amount of water in feed gas stream. TEG dehydration systems may be contained in one or two modular skids, while large system, require several skids and many site work at mid- or large-size production facilities.

Main Equipment List of TED Dehydration Unit:

· Contactor Column (Absorber)

· Glycol Reboiler

· Glycol Regeneration Still

· Still Overhead Condenser

· Glycol Flash Drum

· Glycol-Glycol and Gas-Glycol Exchangers

· Air Cooled Exchangers

· Gas-Liquid Separators

· Filters

· Tanks and Drums

· Glycol Circulation Pumps

· Fresh TEG supply pumps

· Safety Equipment

· Instruments

· Valves

· Control & Automation Equipment

· Piping

Gas Dehydration_)2 (1).jpg)

HC offers technical solution, fabrication and site services for TEG Gas Dehydration Units both for international and domestic markets. Our facility is ISO- and ASME-certified offering large and clean space for assembly and workshop instrument calibration and other electrical works. Feel free to contact HC Petroleum Equipment if your project requires gas dehydration system, gas sweetening and other gas processing equipment.