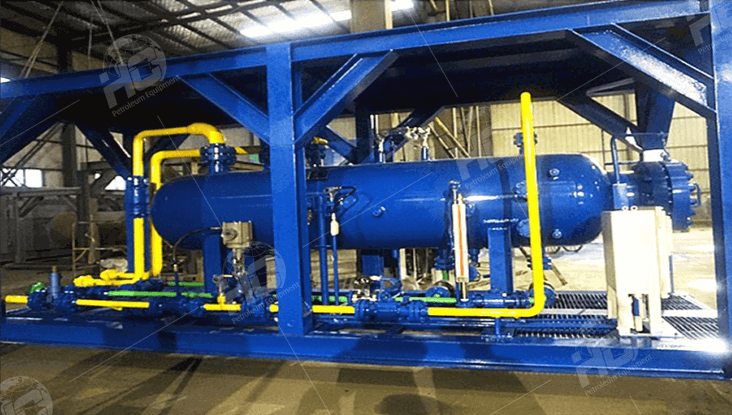

HC Supplies High-Pressure Three-Phase Separator for Sour Service in the Kazakhstan Project

Recently, HC has supplied a high-pressure three-phase separator for a significant project in Kazakhstan. Tailored to meet the specific requirements of the client, this separator is engineered to excel in challenging acidic environments, showcasing HC's commitment to delivering cutting-edge solutions in the oil and gas industry.

Responding to the unique demands of the project, the high-pressure three-phase separator is designed to operate seamlessly in the presence of acidic gases. This customization reflects HC's dedication to understanding and meeting the distinct needs of its clients in diverse operational environments.

This separator incorporates advanced engineering features specifically geared towards withstanding the corrosive nature of acidic environments. The utilization of corrosion-resistant alloys and specialized coatings ensures the longevity and reliability of the equipment under harsh conditions.

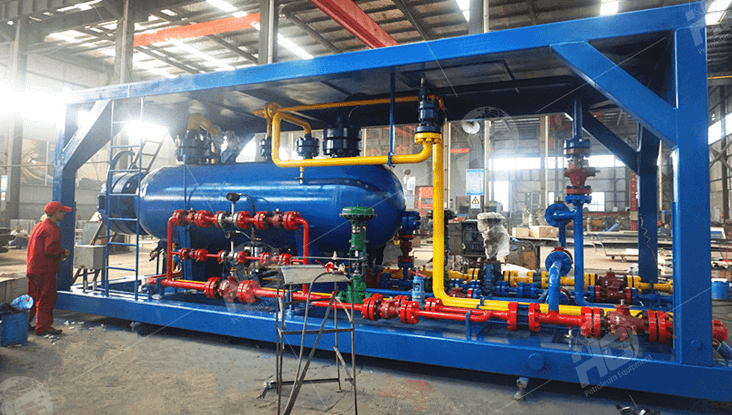

Key Performance Highlights

Efficient Phase Separation: The separator guarantees efficient separation of oil, water, and gas even in the presence of acidic elements, optimizing resource extraction processes.

Corrosion Resistance: Critical components, including pipelines and valves, are constructed from materials with exceptional corrosion resistance, enhancing the lifespan of the separator.

Adaptability to Varying Conditions: Operating in real-world scenarios, the separator showcases adaptability to fluctuating flow rates, pressure changes, and diverse acidic gas compositions.

HC's commitment to industry standards is evident in the separator's design and operation. The equipment adheres to stringent safety measures and environmental regulations, ensuring the highest standards of performance, safety, and sustainability.

As the oil and gas industry continues to evolve, HC remains at the forefront, delivering solutions that meet the unique challenges presented by diverse operational conditions.