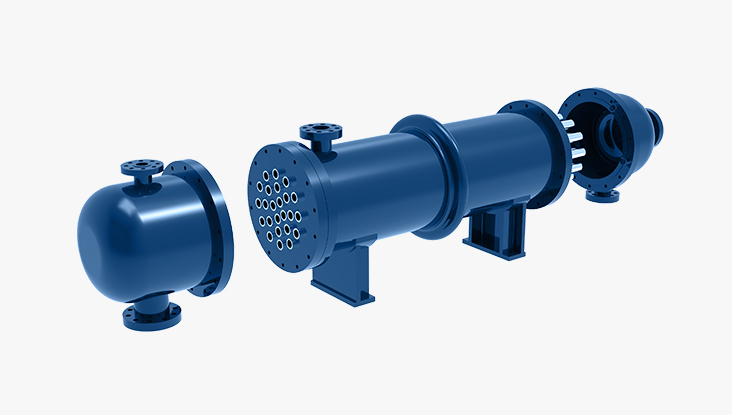

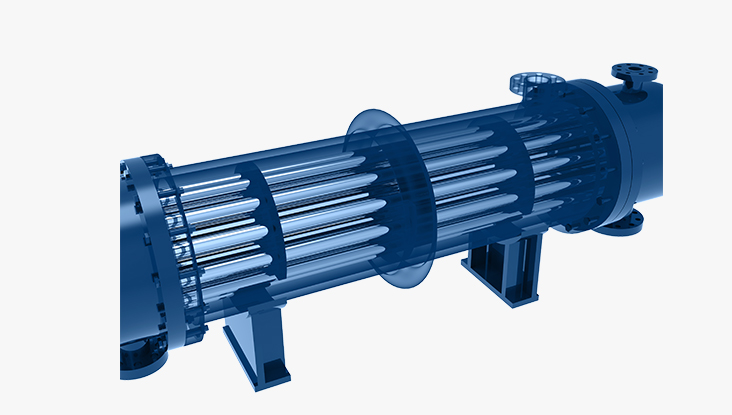

Shell and tube heat exchanger, also known as the tubular heat exchanger, is an inter wall heat exchanger with the wall surface of the tube bundle enclosed in the shell as the heat transfer surface. This kind of heat exchanger is simple in structure and reliable in operation. It can be made of various structural materials (mainly metal materials) and can be used under high temperature and high pressure. It is the most widely used type at present.

Precautions for heat exchange tube replacement of shell and tube heat exchanger:

1.The tube surface shall be free of cracks, folds, heavy skins, and other defects.

2.When the tubes need to be spliced, only one welding joint is allowed for the same heat exchange tube (U-shaped tube can have two welding joints). The length of the shortest tube shall not be less than 300mm, while that of the U-shaped tube bend section shall be at least 50mm. There shall be no splicing weld in the long straight tube section. The amount of butt joint misalignment shall not exceed 15% of the tube wall thickness, and shall not be greater than 0.5 mm.

3.The hardness of the tube shall be checked when the tube and tube sheet are expanded. Generally, the hardness of the tube shall be 30HB lower than that of the tube sheet. When the hardness of the tube is higher than or close to that of the tube sheet, both ends of the tube shall be annealed, and the annealed length shall be 80~100mm longer than the thickness of the tube sheet.

4.Both ends of the tube and the tube plate hole shall be clean and free of grease and other dirt, and there shall be no longitudinal or spiral marks that affect the expansion and tightness.

5.Both ends of the tube shall extend out of the tube plate, with a length of 4 ± 1mm.

6..Hydraulic expansion shall be adopted for the expansion joint of the tube and tube plate. Each bulge shall be re-inflated no more than twice.

7.When the tube and tube plate are welded, the cut surface of the tube shall be flat without burr, bump, crack, interlayer, etc., and there shall be no slag, iron oxide, oil scale and other debris affecting the welding quality.

-

2026 / 02 / 13Skid-mounted Thermally Activated Advanced Oxidation Process (AOP) System for Chemical Wastewater Treatment

-

2025 / 12 / 29

Customized Shell and Tube Heat Exchanger for Syria Project

Customized Shell and Tube Heat Exchanger for Syria Project -

2025 / 11 / 01

HC Successfully Delivers Gas-Liquid-Sand Separator for Xinjiang Oilfield Project

HC Successfully Delivers Gas-Liquid-Sand Separator for Xinjiang Oilfield Project

- +86 158 6190 3617