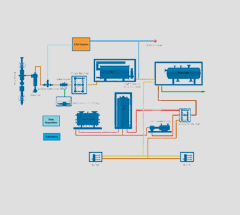

HC Petroleum Equipment provides comprehensive oil and gas engineering & design services, as well as process equipment for well development, drilling operation, well testing, crude oil production and treatment, natural gas field production and treatment, flow control, oilfield facility control and metering, gas treatment and processing, petroleum refining, petroleum storage facilities, loading and transmission equipment.

The oil & gas industry is essential for today’s economy, when petroleum & natural gas remains the major source of energy for people and facilities, as well as the materials for the many interconnected industries. With deep consideration to the climate change due to the carbon dioxide emission, which causes global warming, and leads to many catastrophic events and devastating impact on the environment, more and more energy companies are switching to the renewable source of energy, which comes with bigger financial costs nowadays. Considering China’s technological development and manufacturing power, we are determined to provide cheaper and quality services and products to the world.

Our solutions and services are much more effective in terms of investment and delivery of service provision and equipment supply in compared to other competitors. Our rich experience and dedicated engineering and project management teams can provide high-class standard product and services.

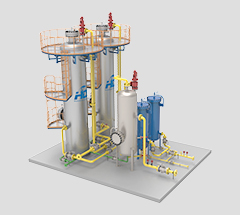

HC provides EPC (Engineering, Procurement, Contraction) services for small gas treatment and processing facilities, as well as oil production, treatment, desalting, dehydration and storage facilities. We also able to work on EP basis, when HC will provide all engineering services, static and auxiliary equipment, as well as materials for the construction, which are not available in local market where particular project is implemented. The works will be conduct as per HSE policies which minimize the adverse impact to the environment and avoid the risk related to human injuries and casualties.

Being complex industry and one of the most hazardous, it requires smart and professional planning and management with deep consideration to the rules of health, safety and environment (HSE). As each well development, oil and gas production facilities, equipment and systems used for refining and processing require huge amount of investment, it is important to make smart planning and choose the proper solutions for each stage of the work. Team of HC Petroleum Equipment has a rich experience, production capacity and perfected network and supplies, offers the contracts and operators faster solutions and lower investments.

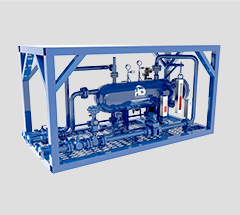

HC Petroleum Equipment’s fast-track field facilities, such as crude oil treatment, dehydration, desalting, loading and transporting, are provided with completed process, piping, electrical design and engineering, which enables the contractors and operators to save funds for other exploration and development projects. Also, saving funds and fast turnover of the investments enables the operators to invest more funds in research & development.

Team of HC Petroleum Equipment consists of qualified and experienced engineers, as well as the partnering engineering institutes, who can provide comprehensive in following disciples

- Automation

- Fabrication

- Field services

- Concept design

- Electrical design

- Echanical design

- Mechanical design

- Laboratory analysis

- Process simulation

- 2D and 3D modelling

- Civil design of facility

- Detailed Engineering

- Project Management

- Piping and layout design

- Trainings of the personnel

- Supply chain management

- Process planning and selection

- Mobile trailer-mounted concept

- QA/QC program and inspections

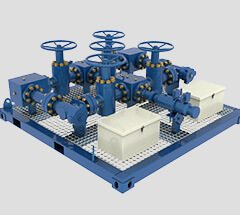

Based on the concept of smart procurement policy of the company, and intelligent management, HC Petroleum Equipment has perfect network of suppliers for materials, such as steel products, pipe and fittings, flow control equipment (API-certified), instruments, electrical & automation equipment (CE/ATEX-certified). Keeping some of the frequently consumed materials in stock in our workshop and warehouses, we deliver materials to the clients and projects, leaving them in maximum satisfaction from the cooperation. Materials are supplied in compliance with American, European, Korean, Russian quality standards, such as CE/PED, ASME, API, GOST and other standards. Our team is very flexible in integration of the product into the local market due to the existing experience and agents all around world.

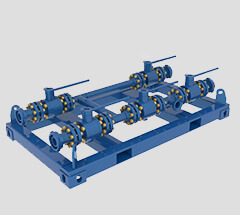

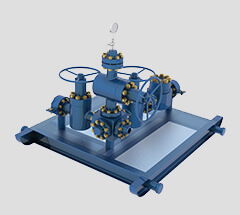

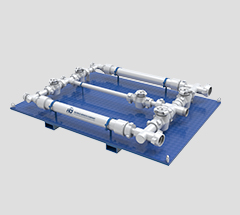

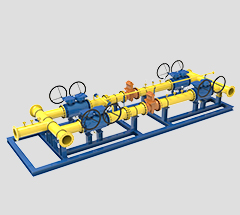

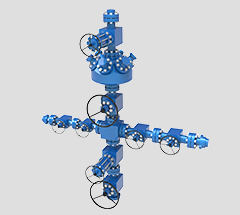

HC Petroleum Equipment is one of the few companies in China, which can provide complete packages of the facilities, such as surface well test facility, offshore well test facility, early production facility, gas field treatment facility, gas processing facilities, loading and storage equipment for petroleum and natural gas.

One of the most complex equipment, such as separator skid or acid removal unit, requires professional approach, strong engineering and fabrication. HC Petroleum Equipment is able to deal with any kind of client requirements to the package, such as its instrumentation & valve brands, strict quality control and inspection, special-material application, integration of the control and electrical systems, including integration to the policy and local language of market where package will be used.

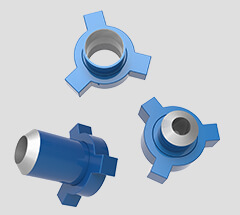

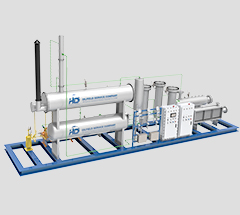

HC also provides fabrication services of special-alloy equipment, such as shell & tube heat exchangers made from titanium alloys (TA2 or another grade) are very especial for chemical processing plants, chlorate manufacturing facility, sulfur recovery units, hydrocarbon processing facilities, desalination process, power generation and many other applications, where heat exchanger shall work under acidic and/or high-temperature conditions.

Materials are selected as per ASTM or GB standards and welded under special working environment with constant temperature control and special automatic welding machines. As show in this picture, manufacturing of this shell & tube heat exchanger are conducted in special-designed workshop with consideration to the temperature, when inadequate handling may cause unpleasant chemical reaction during welding.

HC Petroleum Equipment wishes to expand the references of supplies and services around the world and cherish its client’s evaluation and respect.

.jpg)

.jpg)

– gl separation facility, client - MOGE.jpg)