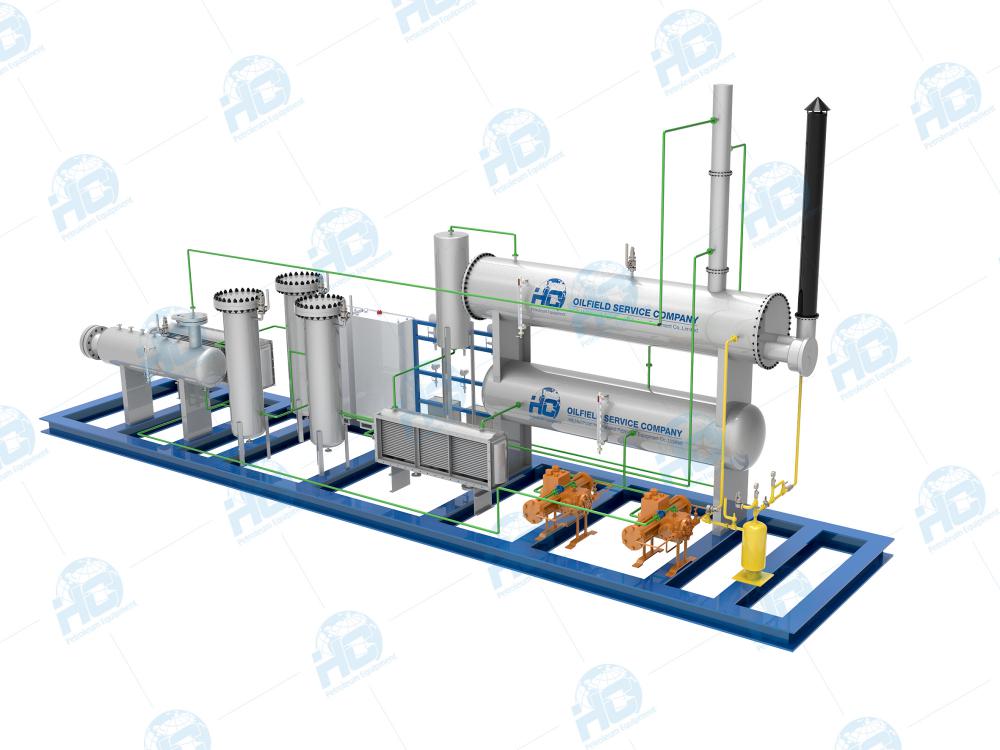

To remove water from natural gas, HC Petroleum Equipment offers reliable and cost-effective glycol dehydration units, which are applicable for onshore and offshore facilities. Glycol dehydration units or TEG dehydration units apply chemical absorption process to remove water vapor from natural gas stream. As glycol dehydration process is a quite mature technology, and with experience and in-house design and fabrication capacities, HC Petroleum Equipment provides gas dehydration units meeting the expectations of the project both for performance and costs. We conduct multiple calculations, software process simulations, mechanical calculation, standard-compliant fabrication, test and inspections to meet the requirements for safety, operability, process, mechanical and transportation. HC adopts “plug-and-play” philosophy, offering mobile and modular systems, which require minimum site works, require less transportation costs and arrive as per project timeline.

Takeaways:

Glycol dehydration units remove water vapor from natural gas by chemical absorption

Glycol dehydration units are supplied as self-contained skid-mounted systems

Glycol dehydration units are custom-made based on the flow rate, water content in natural gas, and other process parameters

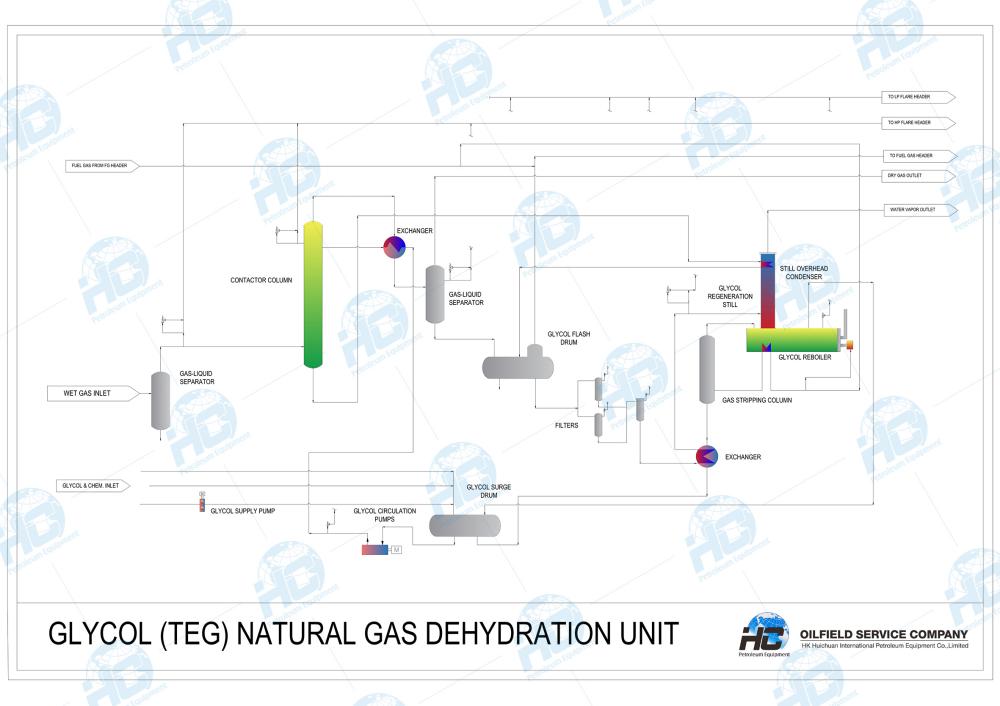

Describing the process, glycols, liquid chemicals, are used for applications where dew point depressions of the order of 33° to 66°C are required. Diethylene glycol (DEG), triethylene glycol (TEG), and tetraethylene glycol (TREG) are used as liquid desiccants, while TEG still is the most common liquid chemical for gas dehydration by absorption process.

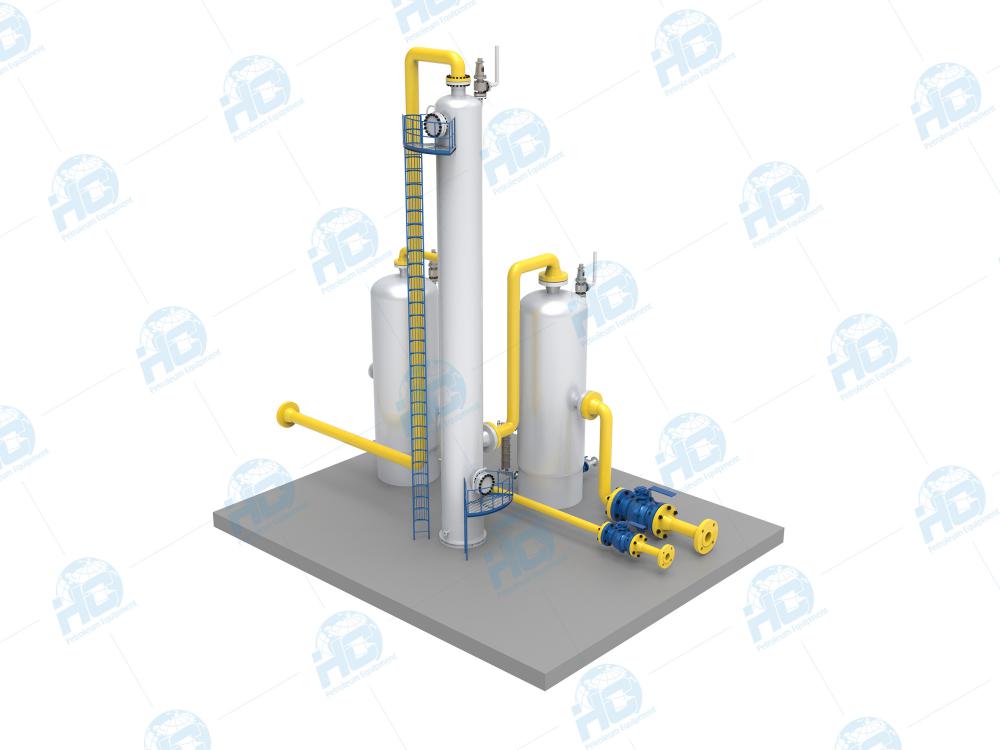

Usually an inlet gas separator is present upstream of the contactor to avoid carryover of liquid water, hydrocarbons, treating chemicals or corrosion inhibitors into the glycol contactor. Unwanted these substances may cause excessive glycol losses due to foaming, reduced efficiency, and increased maintenance. The gas-liquid separators are important for gas dehydration system and shall be designed to handle particular flow rate of gases and liquids to ensure proper gas-liquid separation.

Glycol dehydration columns (trayed columns) include the special internals, packing, which increase gas-glycol contact, increasing chemical reaction, absorption of water by glycol. Lean glycol is pumped to the column and fed to the top of the absorber column, where glycol contacts with water-rich (wet) natural gas stream. Then water-rich glycol is carried out the bottom of the column, and delivered to glycol regeneration section of the gas dehydration system.

Glycol carbon filter is designed to remove the contaminants that are present in an emulsion or solution form in the glycol. Glycol carbon filter apply adsorption process to remove hydrocarbons, contaminants and other liquids that are present in the system. In glycol gas dehydration, a still column is required for glycol stripping using steam or other fluids.

The glycol reboiler is designed to heat the glycol near its boiling point to glycol release its absorbed water and other substances. The glycol reboilers have firetube, burner, fuel gas supply system, and other components, allowing it perform heating and glycol regeneration process. TEG dehydration packages are supplied as modular systems, which are skid-mounted and self-contained with glycol circulation pumps, automation and control systems along with main process equipment.

Feel free to contact HC Petroleum Equipment to receive a quotation and technical support for gas dehydration systems not only by TEG (chemical desiccant), but also for solid desiccant (molecular sieve gas dehydration systems).

.jpg)