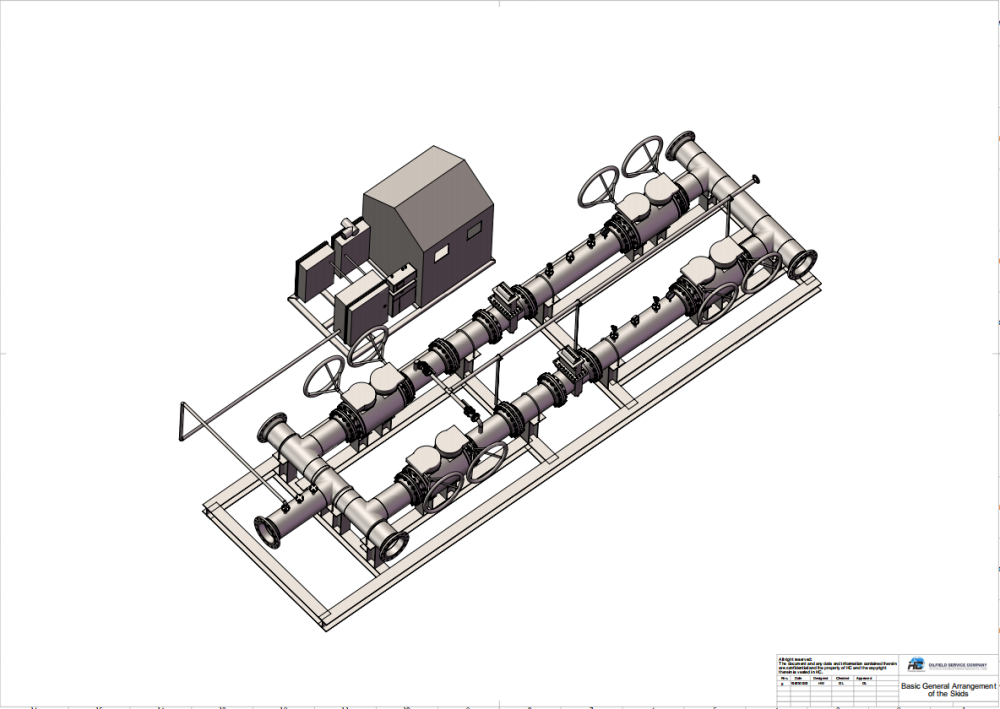

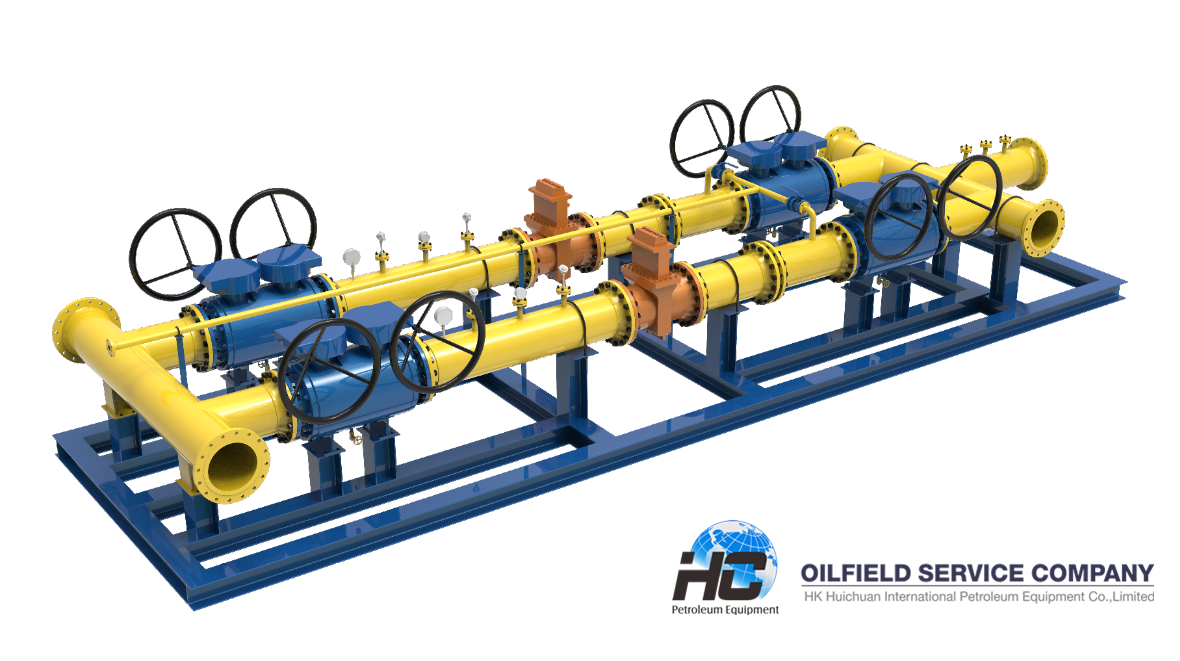

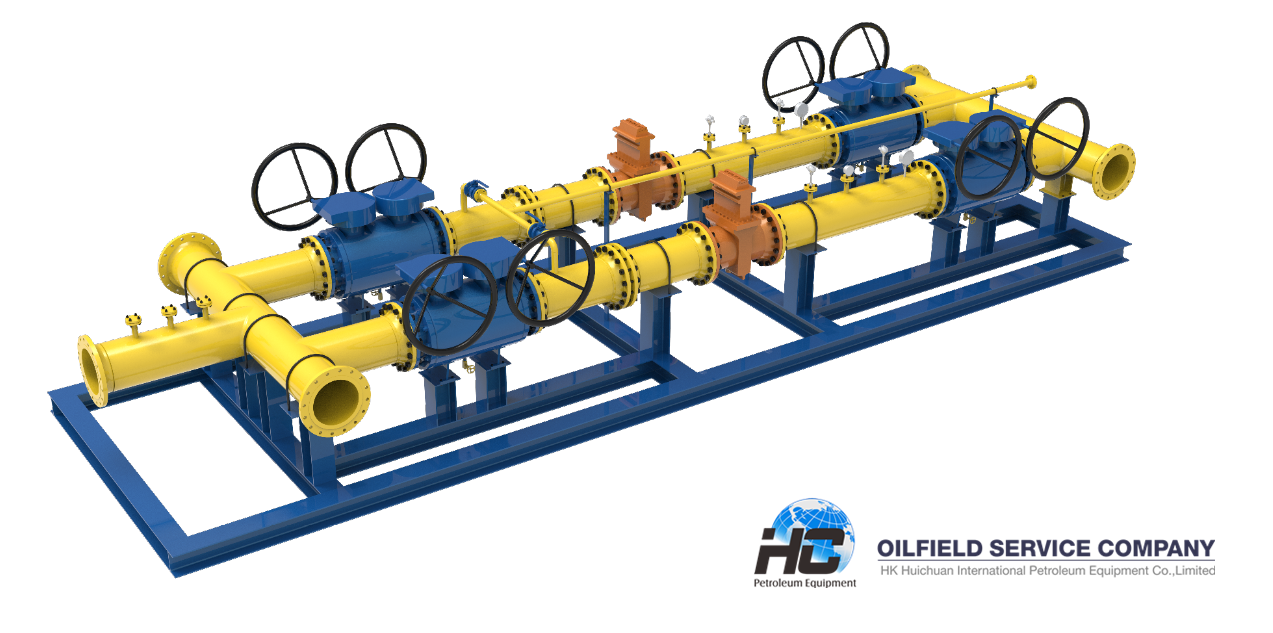

Natural gas metering skid is a special assembly of valve, flow meter, piping and other instruments designed to accurately meter flow rate of natural gas in oilfield production facilities (early production facilities), gas processing plants and other gas receiving/transmission facilities.

Gas metering section are very important of any production, processing and storage facilities because it shows how much gas sold and/or purchased, thus, directly affects profit or gas-purchase expenses. For this reason, governments established special regulations for flow meters and structure of metering skids to ensure consistency of gas metering. Flow meters are the most important device of metering skid is they provide flow data to computer. There are several types of flow meters are available for gas metering, such as orifice plates, coriolis flow meters, ultrasonic flow meter, turbine, and vortex flow meters. Ultrasonic flow meter is considered as most accurate for gas metering, while orifice plate and mass flow meters are also widely applied in gas industry.

Composition and price of gas metering skid are very effected by the level of performance required from metering skid. Gas metering skid may be equipped with special sampling unit, designed to collected samples, condition gas, before gas is sent to analysis. Control room and/or laboratory room may be required to conduct gas analysis. Metering skid may be equipped with H2S, CO2 and water analyzers, which provides additional features to control quality of exported gas and ensure its consistency and pipeline requirements. Piping size depends on flow rate, pressure, temperature and shall be confirmed by the main engineering company and vendor of gas metering skid. I’m cold areas, gas metering skid is required to be thermally insulted and/or put in special modular building and structure. Gas metering skid is also supplied with gauges and transmitters for pressure and temperature monitoring. Some clients may require line filters to remove liquids and impurities from gas stream.

There are several codes and standards which are widely applied worldwide for design and construction of gas metering skids, such as AGA, API, ISO, OIML, CMC, GOST, etc. Regulation for metering skids may vary from country to country. HC has an advantage to supply gas metering skids as per AGA, ISO, CMC. Other standards can be formed too, while it may have slight difference in valve and piping standards, while flow meter brand can be chosen based on the client’s requirements.

Features of HC’s metering skids

· High accuracy of flow

· Space-saving structure

· Equipment factory calibration

· Automation features

· Thermal insulation

· Mounted in modular structure

· Compliance with required regulations

· Quality components, quality welding and assembly

· Fast delivery

· Cost-effectiveness

Main Technical Parameters

· Accuracy + / - 0.5 - 1 % (accuracy depends on type and model of flow meters)

· Compliance with API, ISO, ASME, NACE, ATEX, and other regulatory standards.

· Note: Project requirements shall be confirmed with HC.