HC Petroleum Equipment offers a gas dehydration solution by molecular sieve technology for natural gas treatment and processing. Gas dehydration by molecular sieve is industry-proven process, which offers effective water vapor removal from natural gas stream. In natural gas processing and gas transportation, it is important to remove water vapor to avoid formation of hydrates, corrosion of equipment, and over saturation of natural gas. Molsieve-based dehydration packages are widely used in LNG plants, NGL recovery plants, gas transportation, gas utilization and other process needs. To remove water from natural gas, HC Petroleum Equipment offers molecular sieve gas dehydration units. HC offers in-house design and manufacturing for molsieve-based gas dehydration units along with other gas processing equipment.

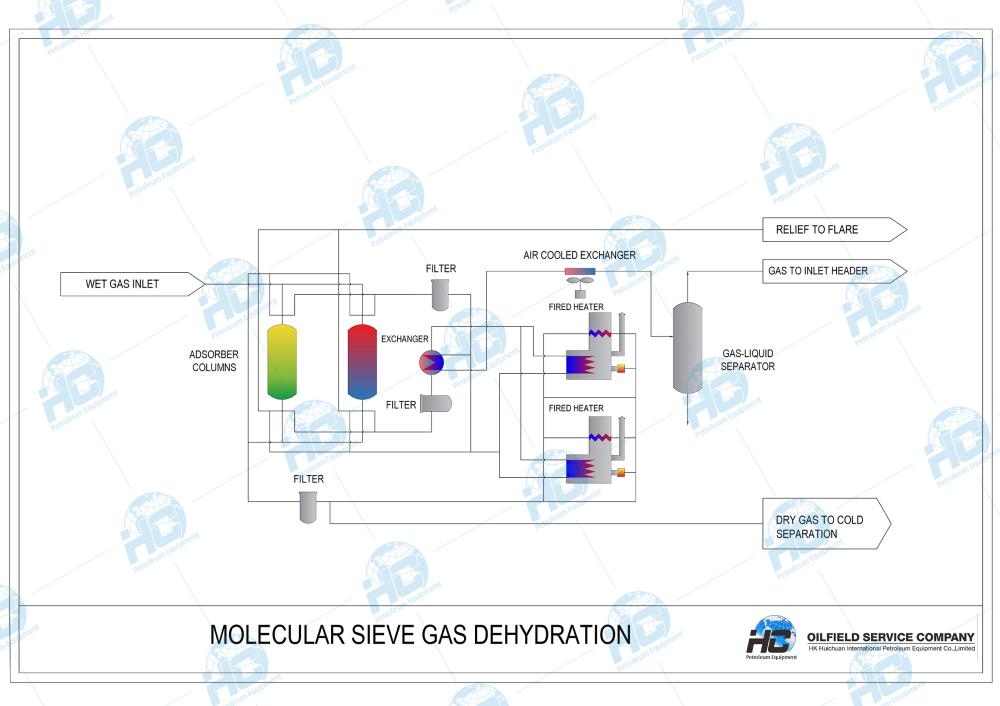

Molecular sieve or mol. sieve process is a very mature technology in gas treatment and processing, mol. sieve gas dehydration units consists of two, three or more columns filled with solid adsorbents, gas filters, and other associated regeneration equipment. Special solid desiccant, zeolite, is placed in columns. Wet gas (water-rich gas) comes in contact with zeolite, and special structure of zeolite captures water in its porous structure. After inlet gas is dehydrated, it becomes dry gas, and dry gas is discharged to utilization or processing. Dry gas is used for utility purposes of oil & gas facility, gas turbines, compressor station (booster compressor station), export, LNG. After dehydration, dry gas may be sent to NGL recovery, LNG, transported and other process needs.

Takeaways:

Mol sieve gas dehydration units remove water vapor from natural gas by adsorption (solid desiccant)

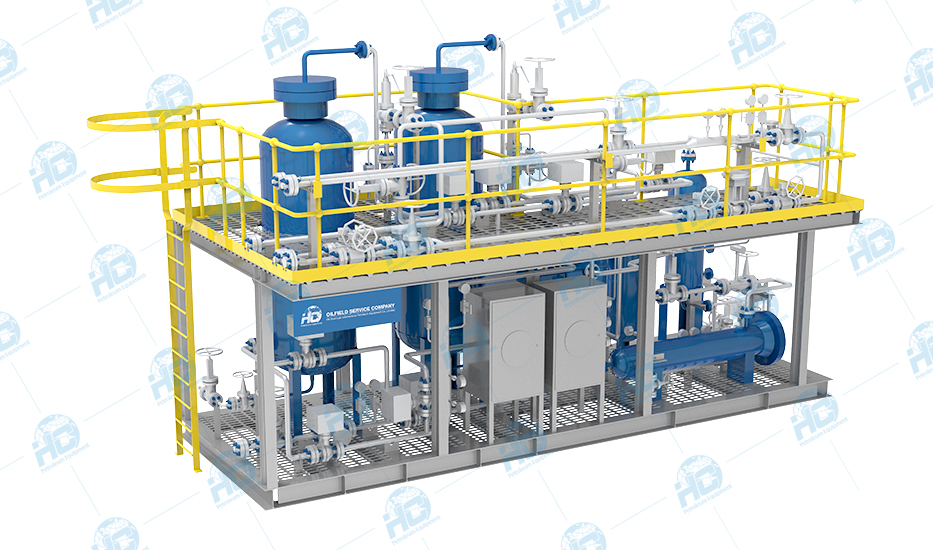

Mol sieve gas dehydration units are supplied as self-contained skid-mounted systems to reduce site works and ease transportation

Mol sieve gas dehydration units are custom-made based on the flow rate, water content in natural gas, and other process parameters

Dry gas may contain very few amount dust and particles of adsorbent, these particles shall be removed by gas filter local on upstream of columns. Filters protect instruments, valves, upstream equipment and piping from short- or long-term damaging. As water is trapped in adsorbent bed, it shall be removed by hot gas. Hot gas is a dry gas, which is heated by special direct fired heaters and discharged to spent bed (water-containing adsorbent bed). In smaller gas dehydration packages, industrial electric heater can be used instead of direct-fired heaters. Hot gas or regeneration gas, is the same gas which is product of the mol. sieve gas dehydration unit. The hot gas turns water to steam, releasing steam from adsorbents as it flows upward through the bed. After hot gas releases water from adsorbent beds, turning it to steam by high temperature, mixed gases (natural gas and steam) are discharged to evaporator. Evaporator condenses steam to water (liquid), and gas-liquid separator separates liquid water from gas. Separated water is drained, while gas is sent to inlet header for dehydration with main flow of wet gas. After regeneration, bed shall be cooled before bed accepts wet gas to repeat the cycle of gas dehydration.

Feel free to contact HC Petroleum Equipment to receive technical support, quotation or other enquiries not only for gas dehydration systems, but also for other gas treatment and processing systems. We would be glad to consider your enquiries and provide immediate response.