Heat Exchanger

Heat Exchanger

Heat exchanger is equipment widely used both upstream and downstream facilities, built for efficient heat transfer from one medium to another. Heat exchangers are classified by flow arrangement, parallel flow and counterflow. Parallel flow (cocurrent) is flow when two fluids enter the exchanger at the same end and travel parallel to one another to the other side. Counterflow (countercurrent) is when two fluids enter the exchanger from opposite ends.

- Coolers:

- Air-cooled

- Cooling towers

- Commonly used types:

- Shell and tube

- Plate

- Plate fin

- Air cooled

In oil and gas facilities, following types are commonly used:

- Commonly used:

- Bath heaters

- Indirect

- Fluid-fluid:

- Shell and tube

- Double pipe

- Plate and frame

Uses of heat exchangers may vary depending on the process requirements, such as heat and cool fluids, heat recovery, separation, reboiling, condensing.

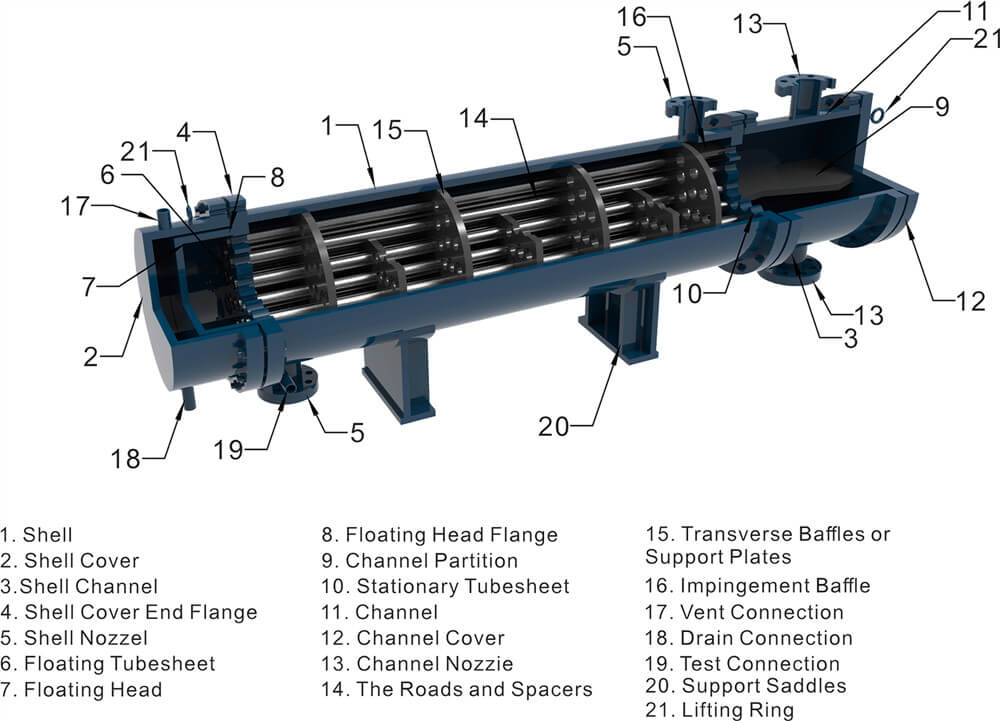

Shell And Tube Heat Exchanger

Shell and tube heat exchangers are mainly used in industrial fields, especially in industries such as chemical, petroleum, pharmaceutical, food processing, and energy.

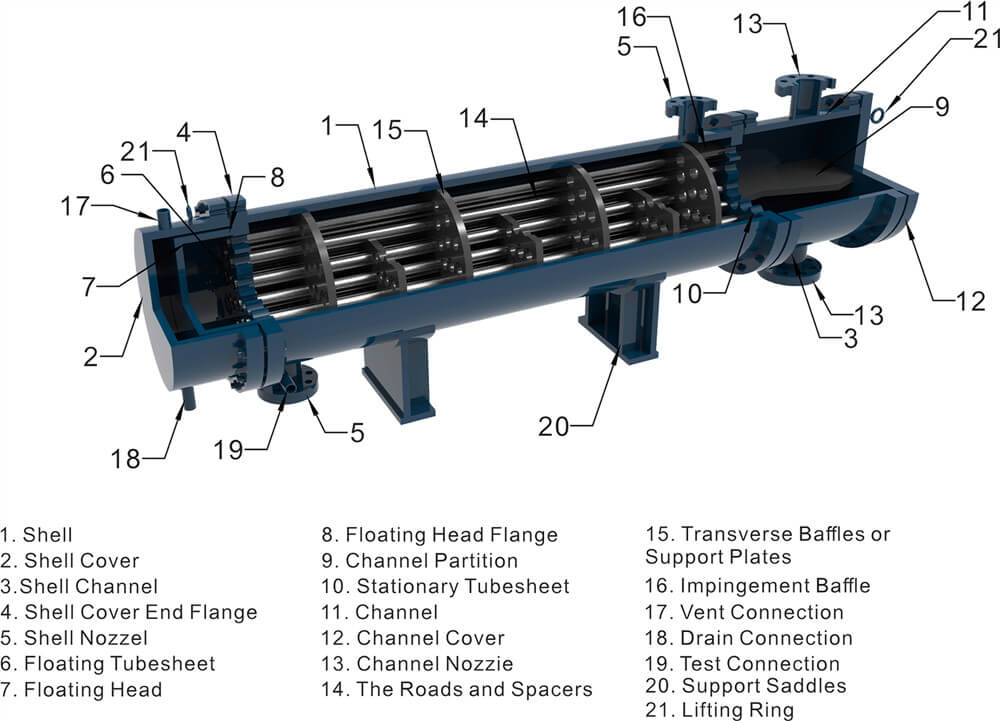

Shell and tube heat exchanger consist of a bundle of tubes and shell. Heat transfer occurs when one fluid that needs to be heated or cooled flows through the tubes and the second fluids runs over the tubes that provides the heat or absorbs the heat required.

Performance advantages

1.Stable and reliable structure: The shell and tube heat exchanger adopts a structure composed of tubes and a shell. Heat exchange occurs between the fluid inside the tubes and the fluid outside the shell. The structure is stable and reliable, capable of withstanding high pressure and temperature.

2.Strong adaptability: The shell and tube heat exchanger can adapt to different process requirements and operating conditions. It can handle different types of fluids, including liquids, gases, and steam.

3.High efficiency: The shell and tube heat exchanger has high heat transfer efficiency, enabling efficient heat transfer, improving energy utilization, and reducing energy consumption.

4.Convenient maintenance: The structure of the shell and tube heat exchanger is relatively simple, making it easy to clean and maintain. This helps reduce downtime and maintenance costs.

5.Strong corrosion resistance: Since corrosive media often need to be handled in industrial applications, the shell and tube heat exchanger is usually made of corrosion-resistant materials. It can effectively resist corrosion and prolong service life.

Configuration

Shell and tube heat exchanger is composed of shell, heat transfer tube bundle, tube sheet, baffle plate and channel. Several baffles are usually installed in the shell. The baffle can increase the fluid velocity on the shell side, forcing the fluid to pass through the tube bundle multiple times in a prescribed way, and enhance the fluid turbulence degree. The heat exchange tubes can be arranged in equilateral triangle or square on the tube sheet. The equilateral triangle arrangement is relatively compact, the turbulent degree of fluid outside the tube is high, and the heat transfer coefficient is large; the square arrangement makes the tube easy to clean and suitable for the fluid which is easy to scale.

Configuration depends on each process requirements. Main consideration for the design should be fluid involved, corrosion potential, problems of cleaning, pressure drop, heat transfer efficiency, tubes usually 20 ft. and 20ft.

Process Principle

A heat exchanger is a device designed to transfer heat between two or more fluids through a solid wall, without direct contact between the fluids. The driving force is the temperature difference between the hot and cold streams, enabling the hot fluid to release heat while the cold fluid absorbs it. Common types include shell-and-tube, plate, and air-cooled heat exchangers.

Working Process

1. Fluid Inlet – The hot and cold fluids enter the heat exchanger through separate inlets, usually with one flowing in the tube side and the other in the shell side (or adjacent channels).

2. Heat Transfer – The fluids are separated by a conductive wall. Heat flows from the hot fluid to the cold fluid, with no mixing, only thermal conduction.

3. Temperature Change – During the process, the hot fluid gradually cools down while the cold fluid warms up until the desired outlet conditions are achieved.

4. Fluid Outlet – After heat exchange, both fluids exit through their respective outlets and continue to the next process stage or pipeline system.

5.Operational Control – Flow rate, pressure, and inlet/outlet valves can be adjusted to regulate heat transfer efficiency and outlet temperature, ensuring safe and stable operation.

The advantages of our shell and tube heat exchanger are as follows: compact and reasonable structure, high heat exchange efficiency, high temperature and high pressure resistance, long service life;smooth inner wall and poor adhesion which is not easy to scale. Please do not hesitate to contact us for stock and quotation.

Shell and Tube Heat Exchanger Types for Oil & Gas Industry

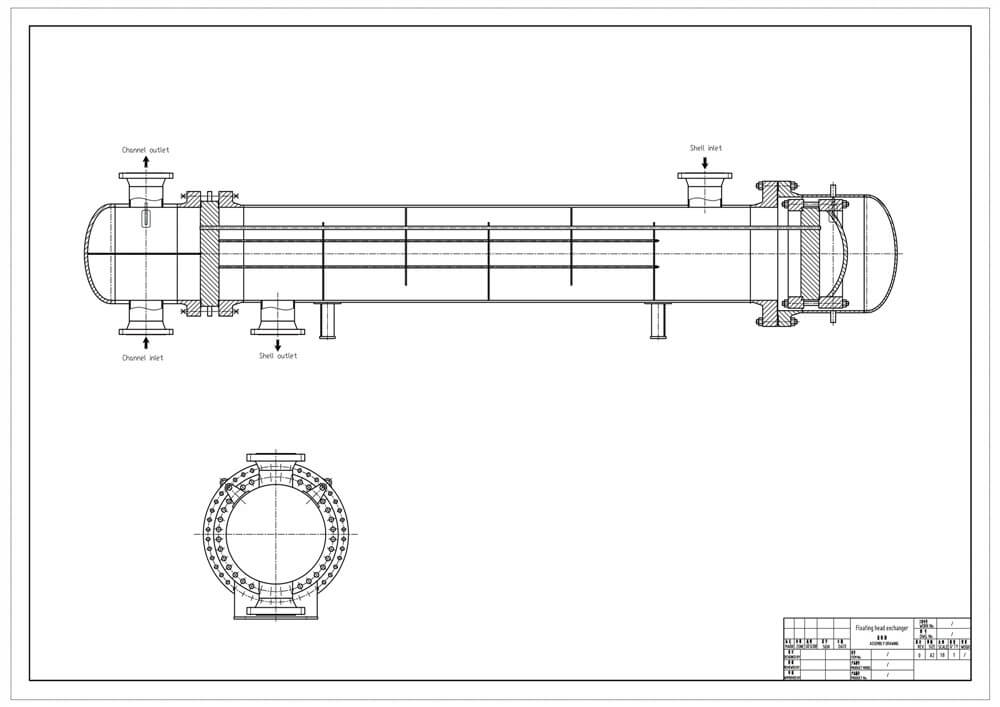

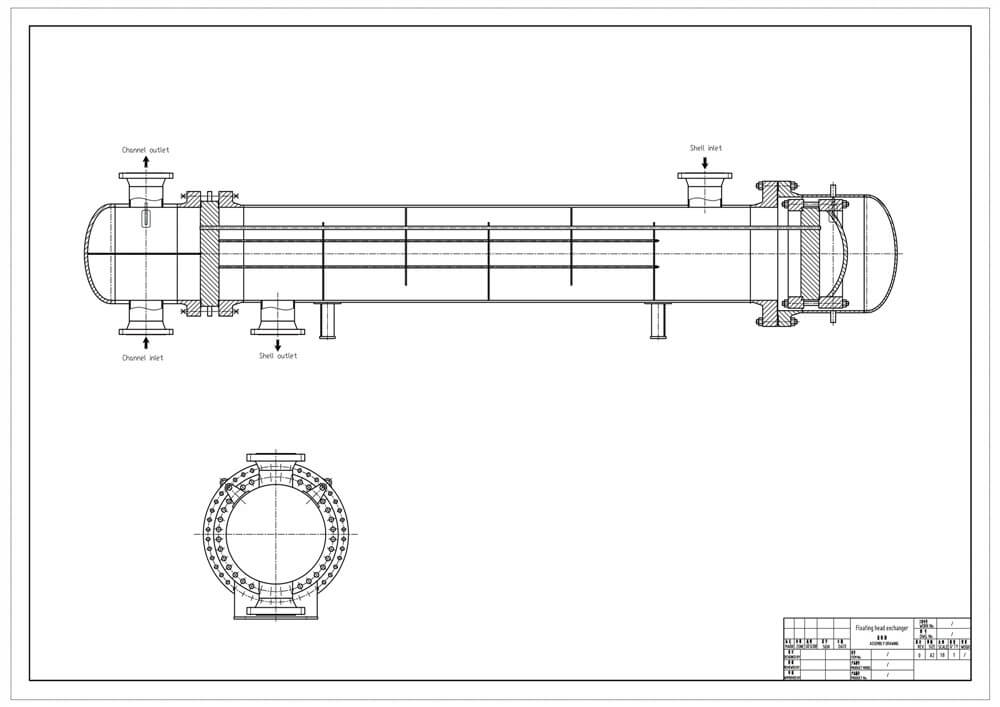

- Floating Head Type Heat Exchanger

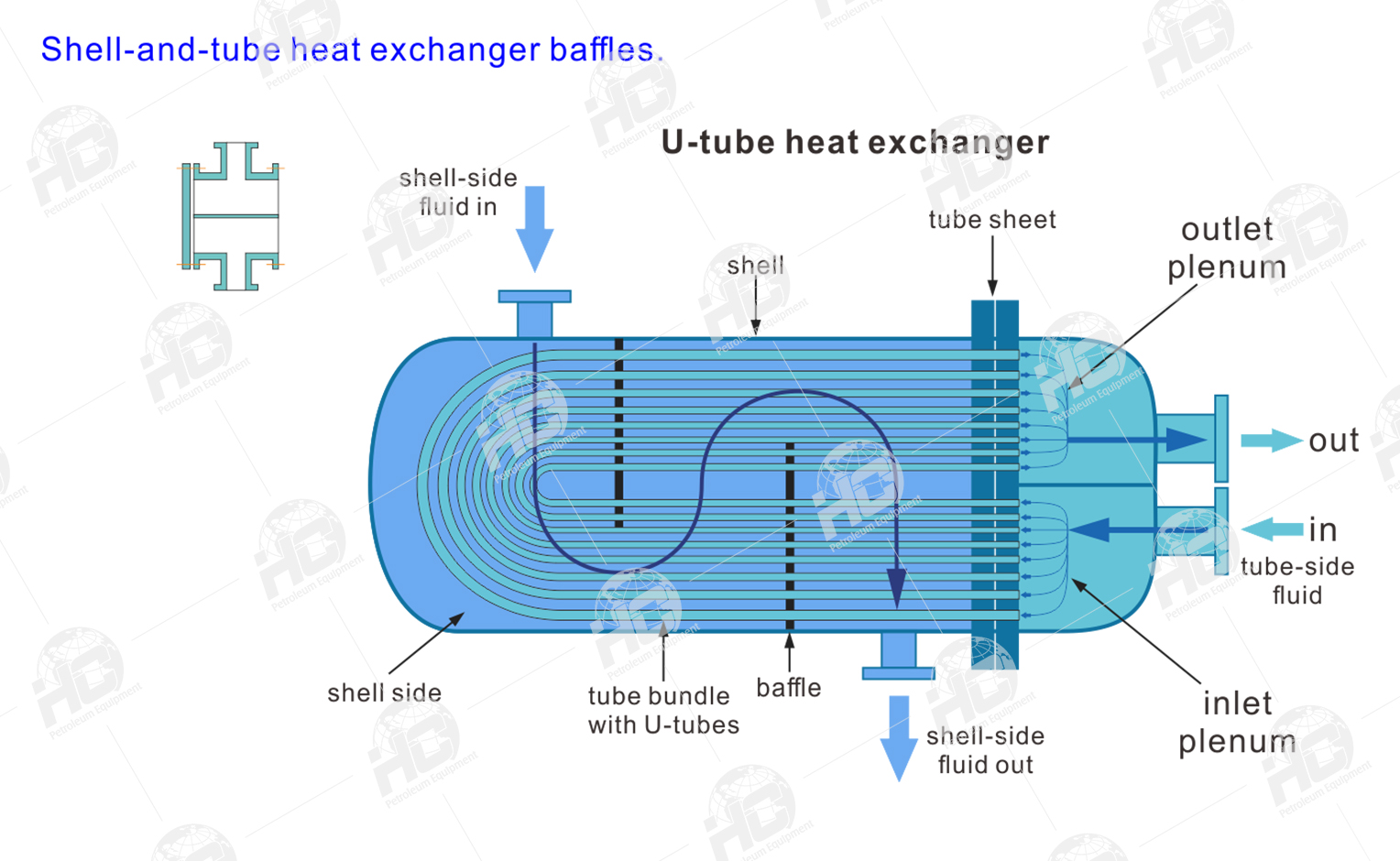

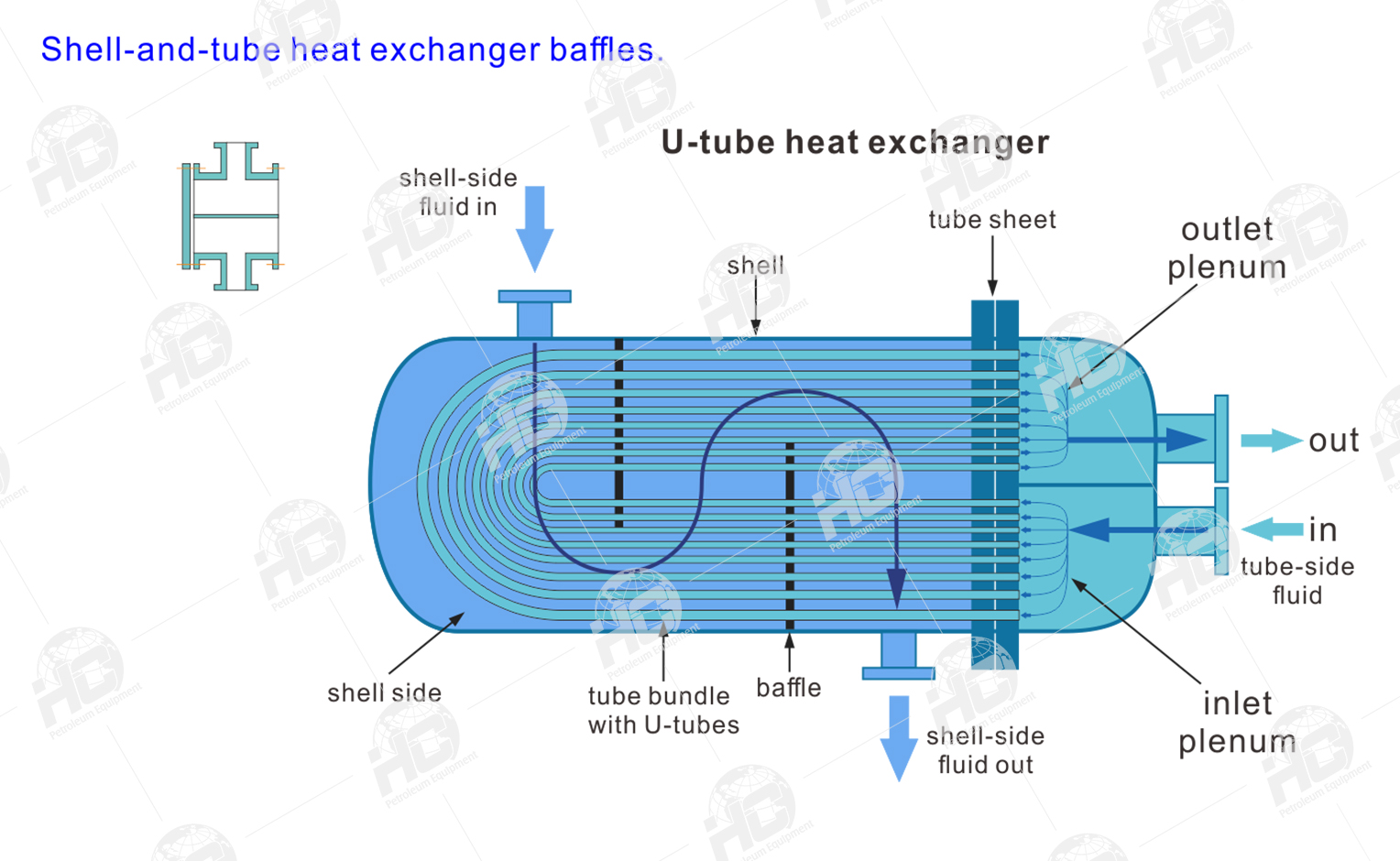

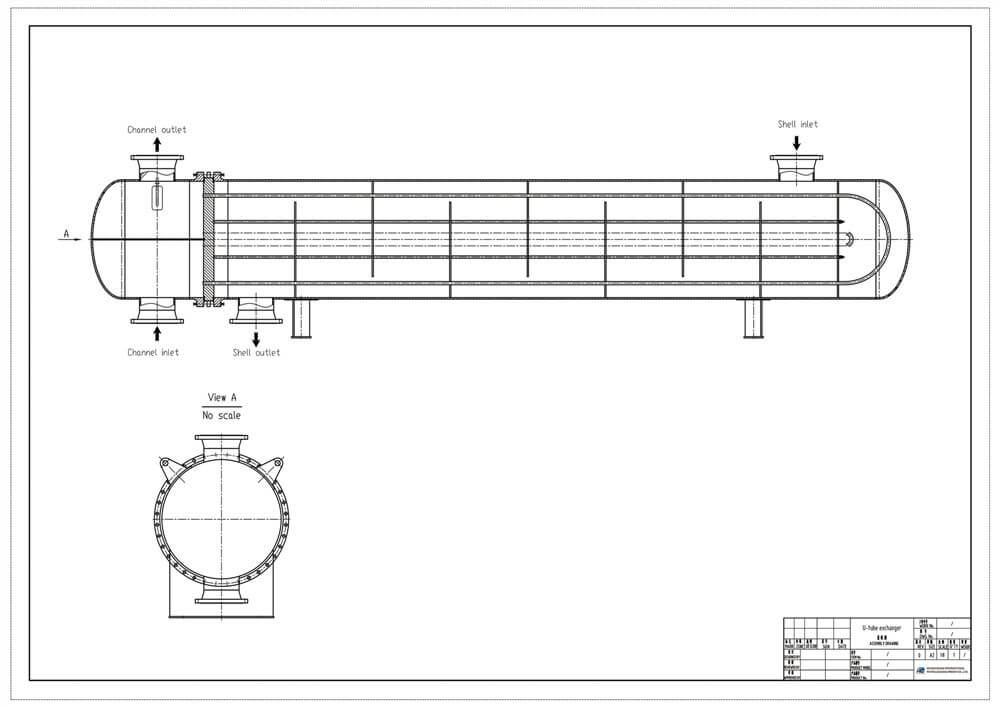

- U-Tube Heat Exchanger

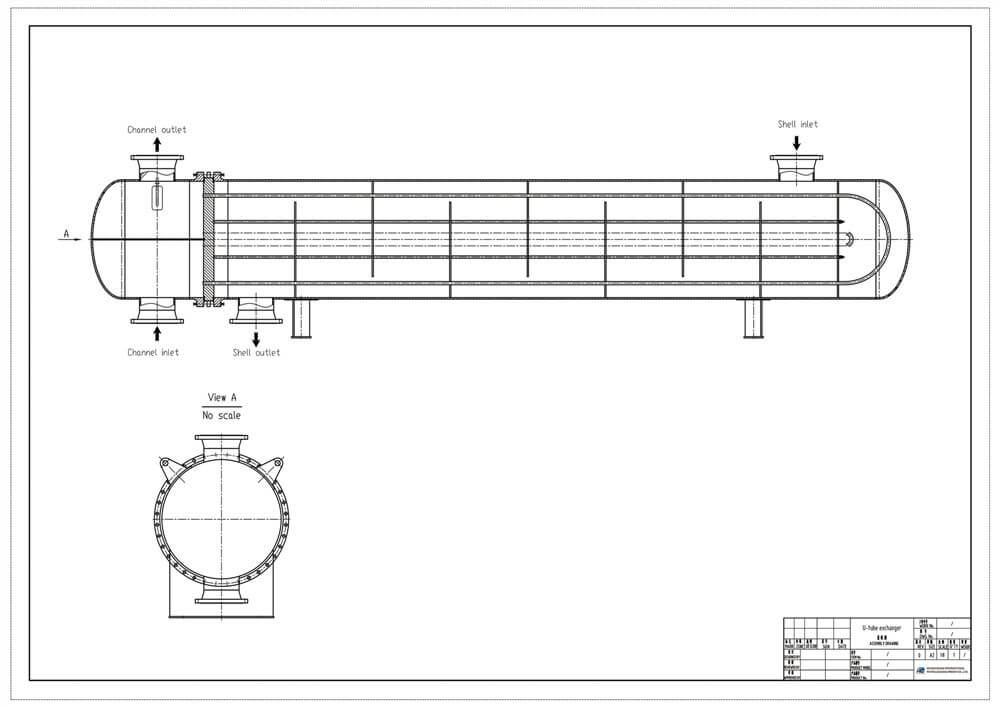

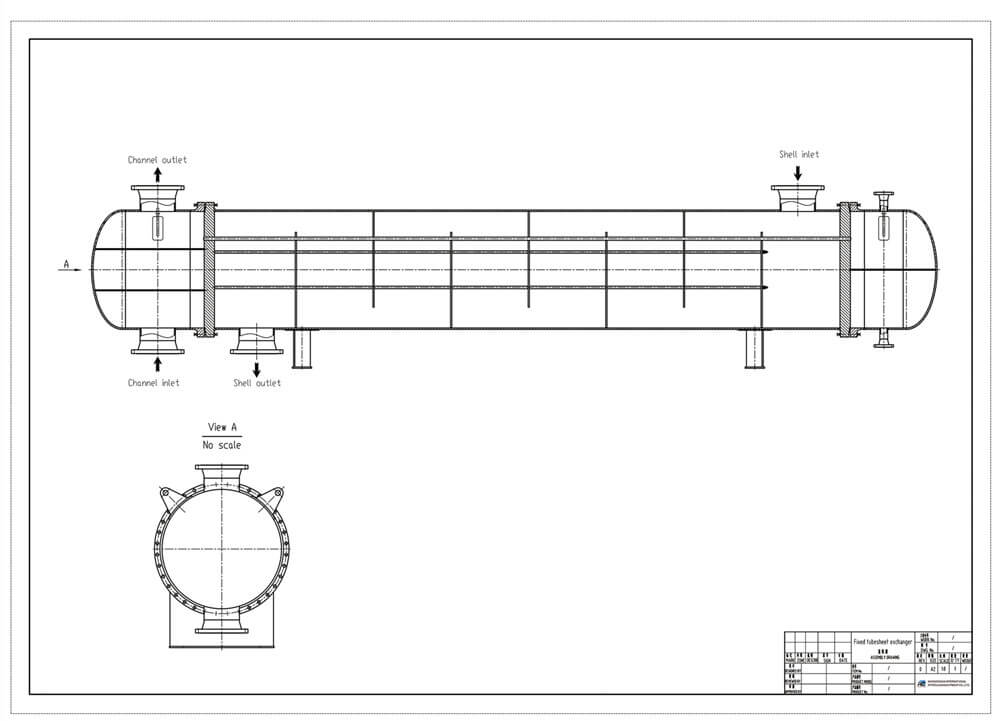

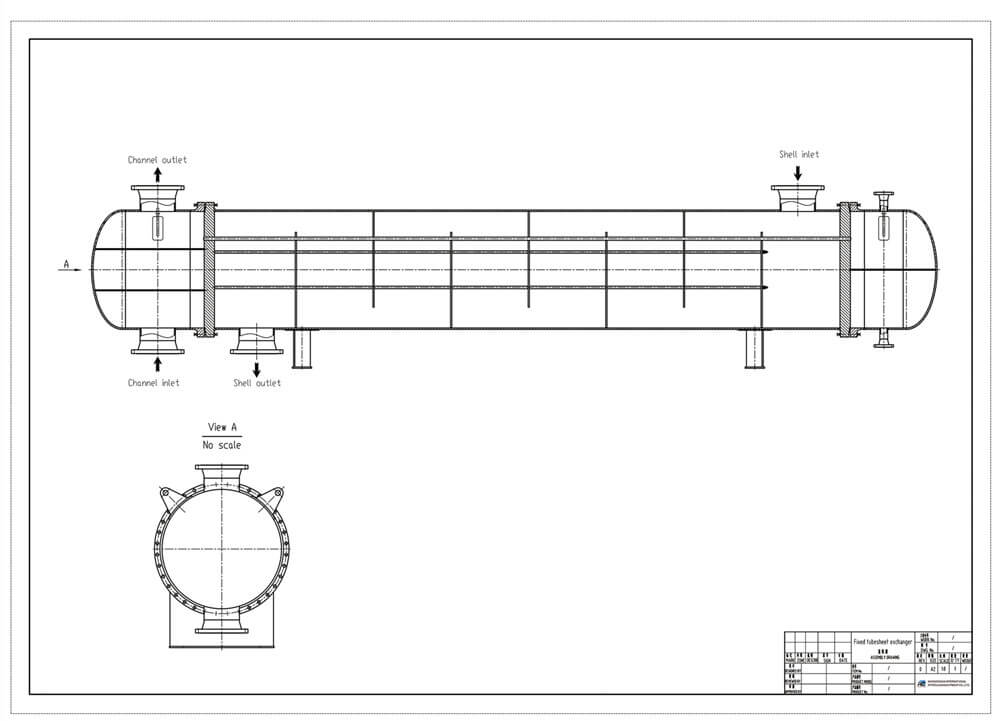

- Fixed Tube Sheet Heat Exchanger

HC provides customized shell and tube heat exchangers including floating head,U-tube and fixed tube sheet designs for oil and gas facilities.

Floating Head

U - tube Heat Exchanger

Fixed tube

Product Photo