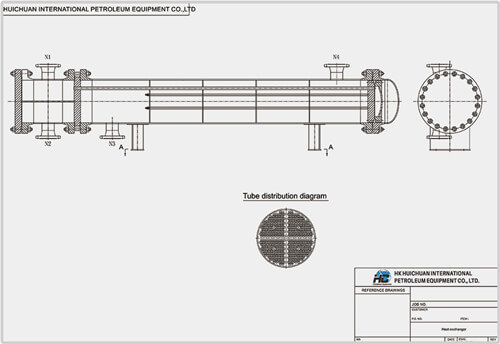

Titanium Heat Exchangers

Shell & tube heat exchangers made from titanium alloys (TA2 or another grade) are very especial for chemical processing plants, chlorate manufacturing facility, sulfur recovery units, hydrocarbon processing facilities, desalination process, power generation and many other applications, where heat exchanger shall work under acidic and/or high-temperature conditions.

Materials are selected as per ASTM or GB standards and welded under special working environment with constant temperature control and special automatic welding machines. As show in this picture, manufacturing of this shell & tube heat exchanger are conducted in special-designed workshop with consideration to the temperature, when inadequate handling may cause unpleasant chemical reaction during welding.

Titanium alloys are the metals, which have the composition of titanium (Ti) and other chemicals, such as carbon (C), iron (Fe), nitrogen (N), Oxygen (O), and hydrogen (H), defined in many grades of local producer’s standards.

Special properties of titanium alloy allow to use materials and products, which are made from it, use in extreme temperatures and hostile working medium. It is praised for high corrosion resistance, high tensile strength and toughness. Titanium can work in 450-500 C° for long period of time. Titanium resists corrosions to alkali, chloride, chlorinated organic substances, sulfuric acid, nitric acid.

For shell & tube heat exchangers, titanium alloys pipes and plates are used for the chemical processing plants, gas processing plants cryogenic vessels and other technologies, which require high performance from the material of the equipment.

Standards, such as ASME SB338, ASTM B338, ASTM B337, ASTM B861, ASTM B862, GB/T3624-2010, GB/T3625-2007, set and regulate the grades of the titanium alloys, and its production. Pipe diameters may vary from 6 mm up to 500 mm. Thickness of the pipes are made from 0.2 mm up to 100 mm. Material grades may differ depending on the application and requirements to the equipment, where materials are used.

- Codes & standards

- Tubular Exchanger Manufacturer Association (TEMA)

- ASME SB338;

- ASME Section VIII, Division 1

- ASTM B338, B337, B861, B862,

- ASME Section I

- GB/T3624-2010, 3625-2007