General Introduction

In case the processed gas flow is so insignificant that it is ignored, the separator is used for two liquid phases separating and it is called liquid/liquid separator. It surely is two-phase separator but the design and structure are basically the same with Three-phase separator, only gas outlet is canceled or combined with light-phase outlet.

Two-phase separator is also called gas-liquid separator. As its name suggests, it is used for separating gas and liquid in wet gas stream, or more generally the gas/liquid stream, when the complex liquid phase components are not required to be separated from each other. Since the stream conditions and required efficiency may vary widely, the Two-phase separator can be designed in many models and with different performances. For instance, a gas/liquid separator upstream of a gas compressor would need to be very efficient, whereas in other cases only bulk separation of the gas and liquid phases is required.

Gas/Liquid Two-phase separator is often used as a buffer/surge/accumulator tank/vessel. Different names show different parts of processed stream behavior and the application emphasis.

Sometimes the key structure or component may also be indicated on separator names, such as vane pack separator and coalesce separator.

Two Phase Separator Advantages:

1.Skid mounted for easy transportation;

2.Dual safety device: rupture disc and spring safety valve;

3.Equipped with automatic control system and integrated blocking manifold system for easy operation;

4.High automation and high measurement accuracy;

5.Clear curves of temperature, pressure and velocity;

6.Continuous operation from beginning to end;

7.ASME certified and meets international standards.

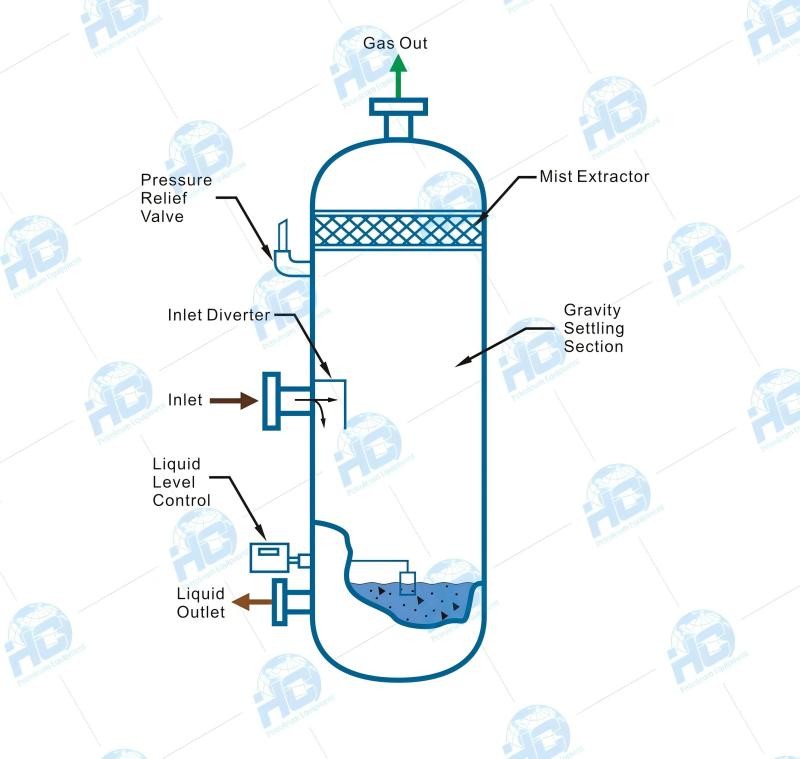

Vertical KO Drum

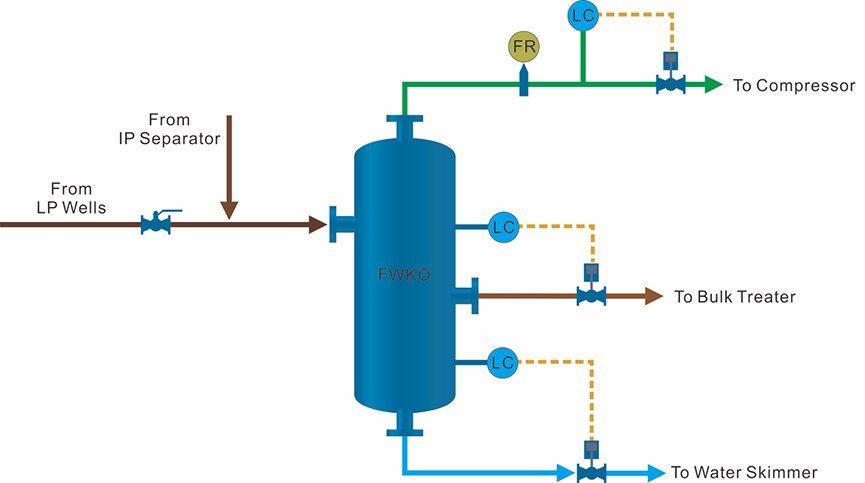

Two-phase separator is also often called knockout drum, KO Drum in short. The “knockout” suggests the free liquid droplets “knocked out” from continuous phase which carry them. For example, a low-pressure free-water KO Drum is so called because it`s designed to separate the free water from wet gas.

Vertical KO Drum is often used for bulk separation of gas and liquid. It has very low pressure drop and takes relatively small ground area to install. It is insensitive to fouling and foaming service.

It is often used to handle fluid with high gas/liquid flow ratio.

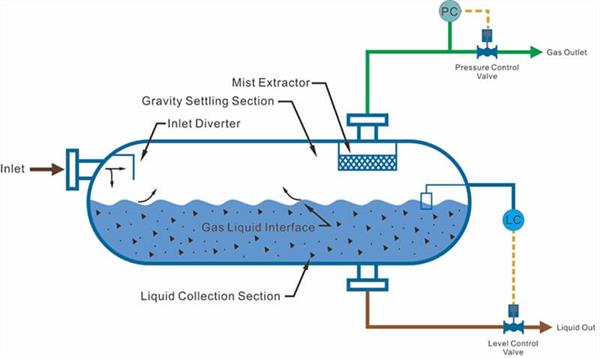

Horizontal KO Drum

Horizontal KO Drum is often used for demisting of gas where a high liquid handling capacity is required. Comparing with Vertical KO Drum, it takes larger ground area and is relatively sensitive to fouling, but gives better water removal efficiency and larger liquid capacity.

For Horizontal KO Drum, mist extractor is often necessary. If the mist extractor (also called as demister mat, mist trap, condensate trap, etc.) is equipped and considered important enough in the KO drum, it will also be called a Demister or Demister Drum.

Horizontal Separator / Vertical Separator

According to the installation mode, the separator can be divided into horizontal/vertical installation, or indoor/outdoor installation.

The horizontal separator is built horizontally, in other words, as the vessel shell axis parallel to the ground. It is usually used for large liquid/gas ratio fluid treatment or liquid/liquid separation. Compared with vertical separators, there are longer horizontal sections for liquid flowing and shorter vertical sections for gravity separation of liquids with different densities. The horizontal separator requires a relatively large horizontal installation space, and its application is generally not affected by the field wind.Horizontal separator can be used for test separator, production separator, two-phase separator, three-phase separator and special application separator.The vertical separator is built vertically, which means the vessel shell axis is perpendicular to the ground. It is usually used for large gas/liquid ratio fluid treatment. Compared with horizontal separators, there are larger cross-sectional area for gas flowing and longer vertical sections for gravity separation of liquids from the gas. The vertical separator requires a relatively small horizontal installation space, but for very high or slender separator the field wind shall be considered.

Vertical separator can be used for test separator, production separator, two-phase separator, three-phase separator and special application separator.

Feature

- Including vertical and horizontal gas-liquid two-phase separator

- Adopt advanced control system

- Durable internals

Code & Standards

- ASME Section VII, DIV 1

- NACE MR0175

- API 12J

- UL, Exp

- PED

- CE

- API 6A, API 6D

- ANSI B31.3 Class M (H2S)

Application

- Exploration well testing

- Extended well testing

- Clean-ups and flowback operations chemical plant

Product Photo