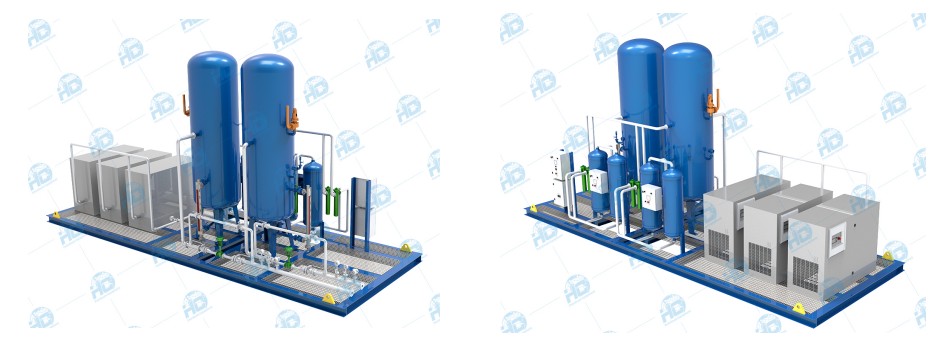

Instrument air supply skid is designed to provide clean compressed air for the process instruments, such as control valves, pneumatic actuators of ON/OFF valves, ESDV actuator, and other instruments. Also, instrument air skid provides compressed air for the needs of the facility. Instrument air supply skid usually consists of two or three air compressors, one or more sets of air desiccant dryers, air filters, control panels, and other auxiliary components. Instrument air skid can be designed with explosion-proof or non-ex-proof configuration depending on the place of installation, zones, and the requirements of the client. HC offers cost-effective, modularized, energy-efficient, and reliable solutions for the instrument's air supply skids. We can customize and modularize the system as per the client’s requirements, as well as offer suitable solutions based on the project specifics.

Features

· Easy to transport and install;

· Modular and integrated system;

· Reliable air compressors with frequency converters;

· Smart control & automation system;

· Applicable for various environmental and working conditions;

· Minimum maintenance;

· Quality assurance;

· Fast-track supply;

· Designed and fabricated as per international code & standards.

Optional

· Ex-proof configuration

· High degree of protection from dust and water

· Special cold-weather service

· Containerization of the system in 20’ or 40’ containers-type structure;

· Offshore application;

· Membrane Dryers;

· Special internal and external coating;

· Test, Inspection and FAT witness by third party;

· Customization.

Application

· Early Production Facilities (EPF)

· Central Production Facilities (EPF)

· LNG plants

· Gas treatment and process plants

· Onshore and offshore oil & gas facilities

· Mobile testing and production facilities

How it works

Process flow diagram provides preliminary insight into the main components and their function in the system, while details are usually specified in the specifications, P&IDs/U&IDs, datasheets, and other technical documents. Air enters air compressors passing through air filters. After the compression, compressed air passes through the exchanger and oil separators. Depending on the air-supply concept of the plant or facility, part of the compressed air can be directed to the utility air receiver and part to the instrument air receiver. Compressed air enters dehydrators (air dryers), which remove water from the compressed air. Before and after the air dryers, there are filters to remove any unwanted liquids and particles from the compressed air for the purpose of supplying clean compressed air to the instruments. Air receivers are usually vertical tanks that keep compressed air and are equipped with pressure gauges, level gauges, PSV, and other monitoring and/or control equipment. There are pressure control valves upstream of the air receivers to regulate flow and pressure to the required value. In short, instrument air compressor skid consists of compression, drying, filtering, and pressure-regulating sections, while configuration, number of the equipment, and components may vary from project to project based on the project specifics.

.jpg)

Feel free to contact HC Petroleum Equipment for more information about instrument air supply packages and other utility equipment for the industrial application. We focus on delivering value to the clients by providing fast and cost-effective solutions for process and utility equipment.