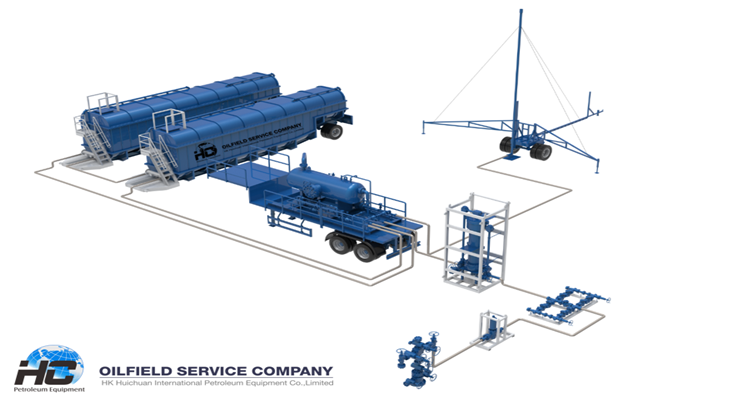

In drilling and flowback operations, it is not easy for operators to ascertain the actual condition in pressure control equipment and the real-time flow rate of fluids and gases. They need to rely on the fracturing flowback system to provide real-time monitoring information and relevant data to analyze, judge and even make critical decisions.

HC Petroleum Equipment is now working with the Middle East Oil and Gas Company on fracturing flowback system and is committed to providing them with safe and reliable equipment with the most cost-effective solution.

Flowback well test equipment that moves gradually from the wellhead downstream, including, but not limited to, debris (junk) catcher, choke pipe, wellhead desander, separator and natural gas flare.

Debris (Junk) Catcher

Debris Catcher or Plug Catcher is designed for bulk removal of debris formed during hydraulic fracturing. Plug catcher has special inserts which catches unwanted substances, cleaning the flow.

Choke manifold

Choke Manifold is an assembly which consist of high-pressure valves and chokes, used for reducing the pressure from the well head. It is operated by opening and closing an adjustable or fixed choke.

Wellhead desander

The wellhead high-pressure desander is suitable for the sand removal operation of high-pressure, high-yield oil and gas wells. It can effectively remove the harmful solid-phase debris such as fracturing sand, formation sand, clay, heavy oil and other objects that affect the surface transportation, testing and measurement.

Separator

A device that uses the difference in gravity and fluid density to divide fluids into two-phase or three-phase systems, which can be generally divided into horizontal or vertical. In order to facilitate movement and transportation, we usually design the separator as a skid-mounted structure, equipped with pipelines, manifolds, valves, instruments and other accessories.

Natural gas flare

The natural gas flare, also known as venting flare, is a device to prevent secondary disasters from accumulating natural gas in stations. In the event of an accident, the safety valve opens automatically, and all natural gas in the station facilities runs to the vent pipe and then the venting flare before burning off.

HC Petroleum Equipment is able to design and manufacture reliable equipment for users, which can meet all production testing and flowback (well test) requirements. On the one hand, our equipment complies with ASME manufacturing standards. On the other hand, our fracturing flowback system can operate normally in any environment, such as high temperature, high pressure, high concentration of hydrogen sulfide (H2S or acid gas). Please feel free to contact us for more solutions.

-

2025 / 12 / 29

Customized Shell and Tube Heat Exchanger for Syria Project

Customized Shell and Tube Heat Exchanger for Syria Project -

2025 / 11 / 01

HC Successfully Delivers Gas-Liquid-Sand Separator for Xinjiang Oilfield Project

HC Successfully Delivers Gas-Liquid-Sand Separator for Xinjiang Oilfield Project -

2025 / 08 / 20

HC Successfully Delivered Filter Coalescer Skid to Malaysia

HC Successfully Delivered Filter Coalescer Skid to Malaysia

- +86 158 6190 3617