When the oil in the formation reaches the wellhead and flows along the outlet pipe and gathering pipe, the oil-gas mixture is formed according to its composition, pressure and temperature conditions. In order to meet the needs of metering, storage and long-distance transportation of oil well products, they must be separated into liquid and gas, commonly known as oil-gas separation.

However, in the later stage of oil well production, oil well products often contain water, and the water content gradually increases. After the water-containing oil well products enter the separator, while oil and gas are separated, part of the water will settle from the crude oil to the bottom of the separator. Therefore, a three-phase separator is needed during this period, which is often called well test three-phase separator.

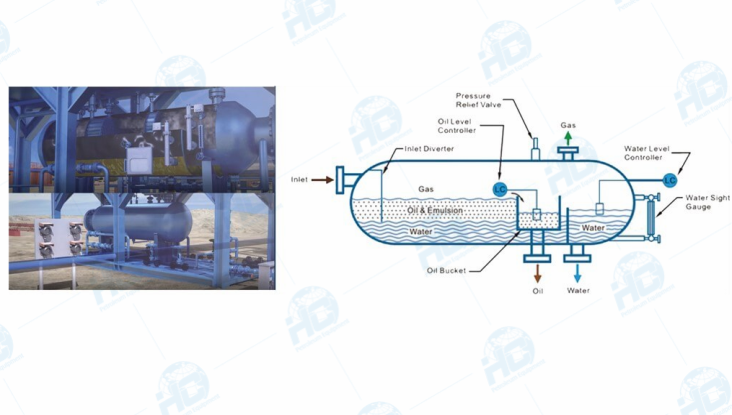

There are two forms of well test three-phase separator, horizontal and vertical. Currently, the typical horizontal three-phase separator is commonly used at home and abroad.

After the oil-gas-water mixture enters the separator, the inlet separator roughly divides the mixture into gas phase and liquid phase. The liquid phase enters the liquid collecting part below the oil-water interface caused by the conduit. The liquid collecting part shall have sufficient volume to make the free water settle to the bottom to form a water layer, on which is crude oil and emulsion oil layer containing small water droplets, and the oil and emulsion oil overflow from the baffle. The oil level at the downstream of the baffle is controlled by the level controller to maintain the opening of the drain valve at the specified height. The gas flows out of the gas outlet after passing through the demister through the gravity sedimentation part. The pressure of the separator is controlled by the valve on the gas pipeline, and the height of the oil-water interface varies from 1/2 to 3/4 diameter depending on the need of gas-liquid separation.

With the continuous improvement of separation technology, the basic structure of well test three-phase separator is constantly enhanced, but its basic working principle remains unchanged. As a sophisticated manufacturer, HC will design and manufacture the three-phase separator according to the specific parameters and working conditions of users. Therefore, to provide customer with detailed technical proposal and cost-effective quotation, basic parameters such as pressure, temperature, medium and flow will be needed.

-

2025 / 12 / 29

Customized Shell and Tube Heat Exchanger for Syria Project

Customized Shell and Tube Heat Exchanger for Syria Project -

2025 / 11 / 01

HC Successfully Delivers Gas-Liquid-Sand Separator for Xinjiang Oilfield Project

HC Successfully Delivers Gas-Liquid-Sand Separator for Xinjiang Oilfield Project -

2025 / 08 / 20

HC Successfully Delivered Filter Coalescer Skid to Malaysia

HC Successfully Delivered Filter Coalescer Skid to Malaysia

- +86 158 6190 3617