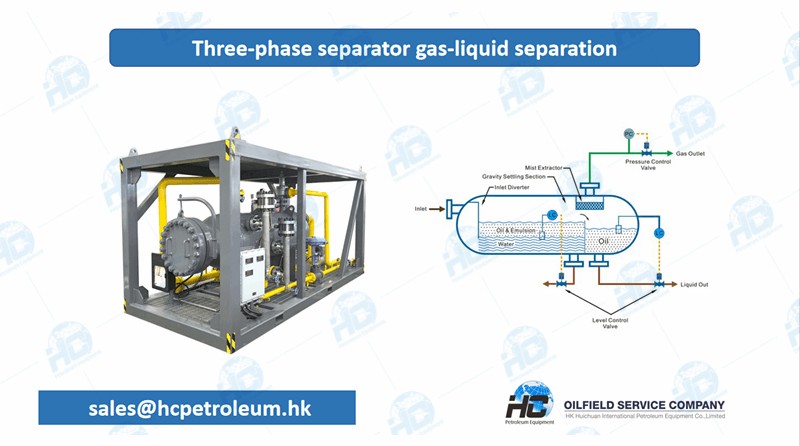

The three-phase test separator is a vital piece of equipment in oilfield testing and natural gas processing. It separates oil, gas, and water phases effectively, ensuring reliable performance in harsh field conditions.

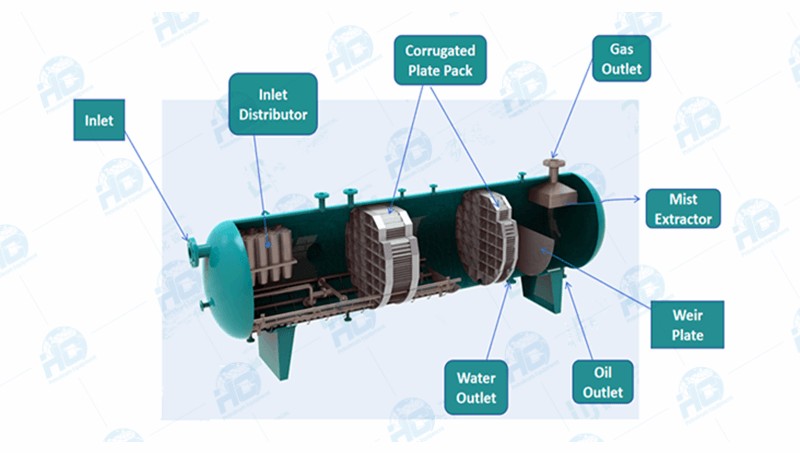

Its internal structure usually varies based on the well fluid composition, on-site conditions, and customer requirements. HC’s horizontal 3 phase separator generally includes: Inlet Diverter (baffle or mesh demister), Corrugated Plate Pack, Weir Plate, Mist Extractor, etc.

The internal operation of the oil-gas-water three-phase separator is a complex process, where each part has its specific function. The common internal components and their functions are as follows:

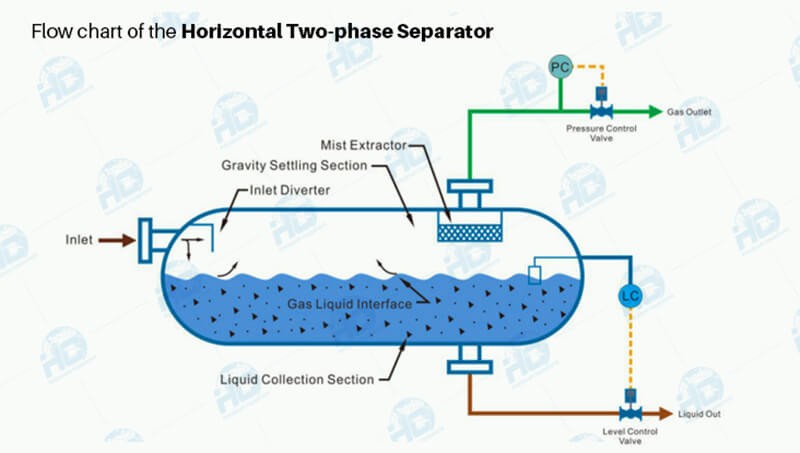

Inlet: A mixture of natural gas, liquid (usually water and oil), and possible solid particles enters the separator through the inlet.

Inlet Diverter: Guides the fluid and slows down its velocity to reduce the speed difference between liquid and gas, providing conditions for subsequent separation.

Mesh Demister: Fluid passes through the mesh demister, where foam or tiny liquid droplets are captured and removed to prevent them from flowing out with the gas.

Corrugated Plate Pack: Fluid enters the corrugated plate pack area, where the corrugated structure extends the residence time of liquid in the separator, promoting better oil-water separation and improving overall efficiency.

Weir Plate: Installed at the end of the separator, the weir plate controls and adjusts the liquid level during the discharge process. It ensures orderly liquid discharge, preventing gas from carrying liquid out of the outlet. By adjusting the liquid level, it enhances gas-liquid separation effectiveness, improving the separator’s performance.

Mist Extractor: Located in the gas channel, the mist extractor further removes tiny liquid droplets from the gas, ensuring the gas meets humidity requirements and reducing the risk of liquid carryover into downstream pipelines.

Gas Outlet: After multi-stage separation, the gas portion exits from the gas outlet for further processing, compression, or transportation.

Oil Outlet: After passing through the overflow baffle, oil leaves the collection area via the oil outlet, ready for storage or transportation.

Water Outlet: Water, sinking in the liquid space due to density differences, exits through the water drain outlet, achieving effective oil-water separation.

In some separator designs, the inlet diverter may directly adopt a mesh demister to capture foam and droplets. The corrugated plate pack extends the residence time of the liquid, which significantly improves oil-water separation efficiency, especially in high water-cut wells.

Applications of Three-Phase Test Separator:

Well testing: Accurate measurement of oil, gas, and water production.

Early production facilities: Continuous and stable separation before permanent processing plants are built.

High water-cut wells: Effective handling of large volumes of water alongside hydrocarbons.

Harsh environments: Optional erosion-resistant materials and sand handling designs.

FAQ (Frequently Asked Questions):

Q1: What’s the advantage of a horizontal 3-phase separator compared to a vertical one?

A1: Horizontal separators provide a larger settling area, making them more efficient in handling high liquid-to-gas ratio wells, and they are easier to maintain.

Q2: What is the typical delivery time for HC’s separators?

A2: Standard models can be delivered within 8–12 weeks, while customized units may take 12–16 weeks depending on specifications.

Q3: What’s the maximum operating pressure of your separators?

A3: Our horizontal 3-phase separators can be designed up to 2160 psi, with customized solutions available for higher pressure requirements.

Q4: Do you provide installation and commissioning services?

A4: Yes, HC offers both on-site technical support and remote guidance to ensure smooth startup and operation.

In summary, the internal structure of each manufacturer’s three-phase test separator may not be exactly the same, as the design depends on various factors including application requirements, well fluid composition, processing capacity, and operating conditions. The design engineers at HC provide tailored technical solutions based on user parameters. We continuously upgrade technology, optimize equipment materials, processes, and structures to deliver higher efficiency and performance.

At HC, our engineering team tailors each oilfield test separator design based on the customer’s basic parameters. With continuous technological optimization in materials, processes, and structure, we help operators reduce downtime, improve separation accuracy, and extend equipment life cycle.

-

2025 / 12 / 29

Customized Shell and Tube Heat Exchanger for Syria Project

Customized Shell and Tube Heat Exchanger for Syria Project -

2025 / 11 / 01

HC Successfully Delivers Gas-Liquid-Sand Separator for Xinjiang Oilfield Project

HC Successfully Delivers Gas-Liquid-Sand Separator for Xinjiang Oilfield Project -

2025 / 08 / 20

HC Successfully Delivered Filter Coalescer Skid to Malaysia

HC Successfully Delivered Filter Coalescer Skid to Malaysia

- +86 158 6190 3617