The extraction of natural gas hydrates, also known as combustible ice, is an exciting frontier in the energy industry. However, the extraction process comes with a set of complex challenges, one of the most significant being the management of sand production. As natural gas hydrates are recovered, sand particles often accompany the gas and water phases, posing serious risks to both equipment and the overall production system. If not properly managed, sand can cause erosion, clogging, and even failure of critical components like pumps, pipelines, and separators. Effective sand removal and prevention are thus essential for the safety, efficiency, and long-term sustainability of hydrate extraction operations.

Sand production occurs when the formation surrounding the gas hydrate reservoir is disturbed during extraction. As gas hydrates are depressurized and extracted, the surrounding formation can become unstable, releasing fine sand particles that mix with the gas and water. These particles, while often small, can be abrasive and corrosive, causing significant damage to pipelines, separators, and other equipment downstream.

Additionally, sand can cause operational challenges such as blockages in pipelines, reduced flow rates, and inaccurate measurements of gas output. The presence of sand also complicates the separation process, as it needs to be removed from the gas, water, and hydrate mixture before the resources can be processed or transported.

Key Strategies for Sand Removal and Prevention

Cyclonic desanders are one of the most widely used devices in hydrate extraction for efficiently removing sand from the gas-water-hydrate mixture. These devices work based on centrifugal force: as the fluid enters the desander, it is spun at high velocity, causing heavier sand particles to be pushed to the outer walls, where they settle. The separated sand is then collected at the bottom of the desander while the cleaner fluid flows out through the top.

Advantages of Cyclonic Desanders:

High Efficiency: Cyclonic desanders can handle high volumes of sand-laden fluid with remarkable efficiency.

No Moving Parts: Since these devices rely on centrifugal force, they have no moving parts, which reduces wear and tear, lowering maintenance costs.

Compact Design: Cyclonic desanders are relatively small and can be used in both onshore and offshore environments where space is often limited.

Mechanical Sand Cleaning Tools

In addition to cyclonic desanders, mechanical methods are often used to remove accumulated sand directly from the wellbore. Tools like sand-cleaning drill strings and scrapers are deployed to physically clear sand deposits from the wellbore. These tools are used periodically to ensure that sand does not accumulate in locations that might hinder gas flow or damage equipment.

High-Pressure Jetting

High-pressure pumps are often employed to inject fluid into the wellbore or the production system to flush out sand particles. The force generated by the high-pressure fluid dislodges and transports the sand to the surface, preventing it from settling in the well or clogging equipment.

Chemical Inhibition

Chemical inhibitors can be introduced into the wellbore to reduce the production of sand. These chemicals help stabilize the surrounding formation, minimizing the release of sand during hydrate extraction. Chemical inhibition is typically used in combination with other physical methods to enhance the effectiveness of sand management.

Prevention Techniques for Sand Production

Sand Control Methods

Sand control methods, including gravel packing, screen completion, and chemical inhibitors, can be applied to reduce sand production from the reservoir. These techniques help to stabilize the formation, preventing sand from entering the production system.

Formation Stabilization

In some cases, formation stabilization through the use of chemical agents can prevent sand from being mobilized during extraction. This is particularly useful in reservoirs prone to significant sand production.

Cyclonic desanders play a crucial role in efficiently managing sand production during natural gas hydrate extraction. By using centrifugal force to separate sand particles from the fluid stream, they help protect downstream equipment and maintain operational efficiency. Combined with other sand removal and prevention techniques, such as mechanical sand cleaning tools, high-pressure jetting, and chemical inhibitors, cyclonic desanders ensure the sustainable and safe operation of hydrate extraction systems. As the industry advances, these technologies will continue to be pivotal in optimizing gas hydrate extraction processes.

-

2026 / 02 / 13Skid-mounted Thermally Activated Advanced Oxidation Process (AOP) System for Chemical Wastewater Treatment

-

2025 / 12 / 29

Customized Shell and Tube Heat Exchanger for Syria Project

Customized Shell and Tube Heat Exchanger for Syria Project -

2025 / 11 / 01

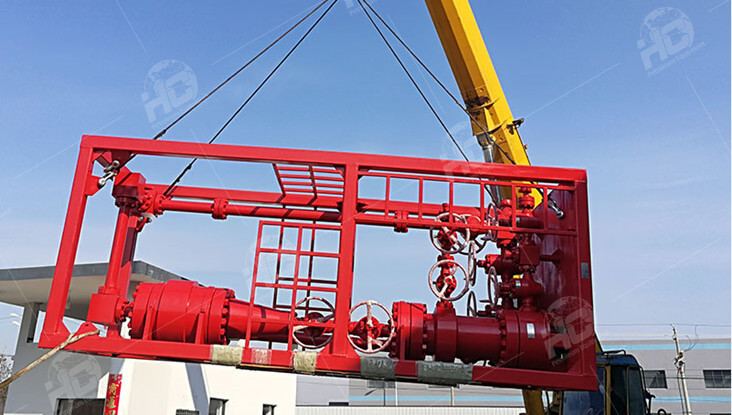

HC Successfully Delivers Gas-Liquid-Sand Separator for Xinjiang Oilfield Project

HC Successfully Delivers Gas-Liquid-Sand Separator for Xinjiang Oilfield Project

- +86 158 6190 3617