In oil and gas production, the choice between a two-phase separator and a three-phase separator is crucial for optimizing efficiency, reducing processing costs, and ensuring compliance with operational and environmental standards. While both types of separators play an essential role in separating well fluids, their application differs based on the composition of the produced fluid, operational requirements, and downstream processing needs.

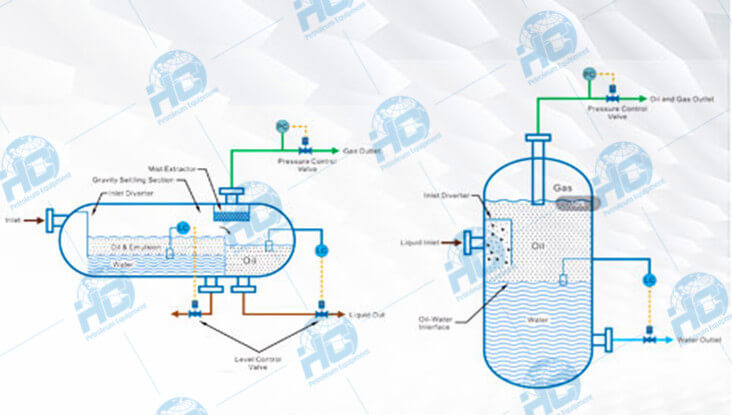

A two-phase separator is designed to separate gas and liquid, where the liquid phase contains a mixture of oil and water. It is primarily used when further oil-water separation is handled by downstream equipment.

A three-phase separator, on the other hand, is capable of separating gas, oil, and water in a single unit. This eliminates the need for additional oil-water separation equipment, reducing processing complexity and operational costs.

When to Use a Two-Phase Separator

Two-phase separators are typically used in situations where oil-water separation is not an immediate concern or when additional treatment facilities are available:

Gas-Dominant Wells: If a well produces mostly gas with minimal liquid, a two-phase separator is sufficient to remove the liquid phase before gas processing.

Centralized Processing Facilities: In some operations, oil and water separation is performed at a central processing station, making a two-phase separator suitable at the wellsite.

Low Water-Cut Reservoirs: If the produced liquid contains very little water, a two-phase separator can handle initial separation, with minor water content removed later in processing.

Cost-Sensitive Projects: Since two-phase separators are simpler in design and typically cost less, they are often chosen when capital expenditure needs to be minimized.

When to Use a Three-Phase Separator

Three-phase separators are essential when water removal is a priority or when a more streamlined separation process is needed:

High Water-Cut Wells: When a well produces significant amounts of water along with oil and gas, a three-phase separator provides efficient phase separation upfront, reducing the load on downstream equipment.

Oil Quality Control: If the goal is to obtain crude oil with minimal water content before transport or further processing, a three-phase separator ensures cleaner separation, reducing dehydration costs.

Field Testing and Well Monitoring: In well testing and production monitoring, it is critical to measure the production rates of oil, gas, and water separately. Three-phase separators provide accurate phase measurements.

Environmental and Regulatory Compliance: Many oilfields must treat produced water before disposal. A three-phase separator allows water to be separated at the source, facilitating proper handling and reducing environmental impact.

Choosing the Right Separator

When selecting between a two-phase and three-phase separator, operators should consider the following factors:

Produced Fluid Composition – If a significant amount of water is present, a three-phase separator is preferred. For gas-dominant production, a two-phase separator may be sufficient.

Processing Infrastructure – If centralized oil-water separation facilities exist, a two-phase separator at the wellsite can be a cost-effective choice.

Operational Costs – While a three-phase separator reduces downstream processing needs, it requires a higher initial investment. Consider long-term operating expenses when making a decision.

Measurement and Monitoring Needs – If detailed phase measurement is required for reservoir evaluation, well testing, or production monitoring, a three-phase separator is the best option.

Regulatory and Environmental Factors – If water disposal regulations are strict, a three-phase separator can simplify compliance by separating water at the source.

The decision between a two-phase and three-phase separator is not one-size-fits-all. It depends on well conditions, processing capabilities, budget constraints, and regulatory requirements. While two-phase separators are cost-effective and ideal for gas-heavy wells, three-phase separators offer a more comprehensive solution for oil and water separation, improving efficiency and reducing downstream processing challenges.

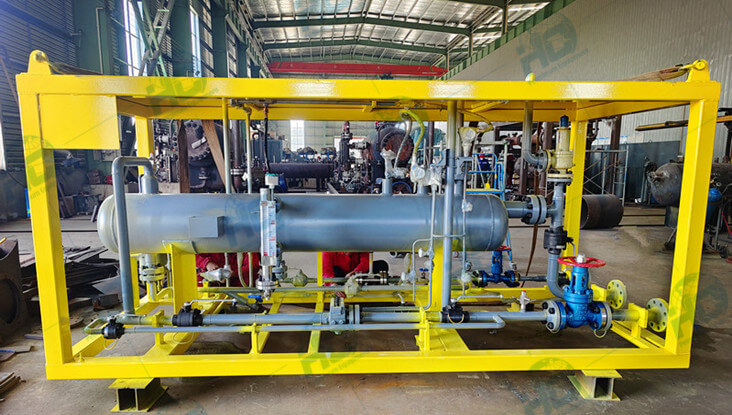

As a leading manufacturer of surface testing and separation equipment, HC provides customized two-phase and three-phase separators tailored to meet the needs of oil and gas field operations. With extensive experience in designing high-performance separation systems, HC ensures efficient phase separation, accurate measurement, and reliable performance in diverse field conditions. Whether you require well testing separators, production separators, or complete surface processing solutions, HC offers engineering expertise, high-quality fabrication, and full technical support to enhance operational efficiency and optimize production.

By carefully evaluating the fluid composition and operational needs, oilfield operators can select the most appropriate separator, and with HC’s expertise, ensure maximum performance and cost-effectiveness.

-

2026 / 02 / 13Skid-mounted Thermally Activated Advanced Oxidation Process (AOP) System for Chemical Wastewater Treatment

-

2025 / 12 / 29

Customized Shell and Tube Heat Exchanger for Syria Project

Customized Shell and Tube Heat Exchanger for Syria Project -

2025 / 11 / 01

HC Successfully Delivers Gas-Liquid-Sand Separator for Xinjiang Oilfield Project

HC Successfully Delivers Gas-Liquid-Sand Separator for Xinjiang Oilfield Project

- +86 158 6190 3617