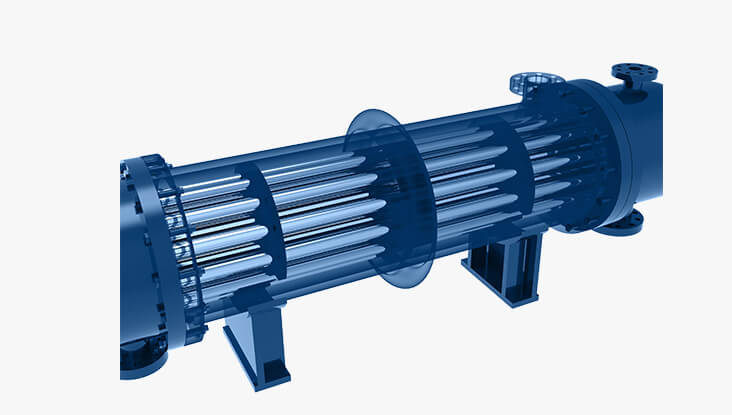

The shell and tube heat exchanger is mainly made of carbon steel, stainless steel and copper. When the carbon steel tube plate is used as the cooler, it is easy to have corrosion leakage if the welding seams between the tube plate and the row tube is not well protected. In order to avoid environmental pollution and material waste caused by leakage into the cooling water system, HC Petroleum Equipment has sorted out some protective measures for your convenience.

1.Using process anti-corrosion

The relatively common preventive measures are desalting, ammonia injection, alkali injection and corrosion inhibitor injection, which can effectively reduce the corrosive substances to the minimum, so as to ensure the normal operation of shell and tube heat exchanger.

2.To enhance the equipment material

Generally, the shell and tube heat exchanger is made of stainless steel in the medium environment with high-temperature and highly-corrosive. However, there are various kinds of corrosion. If stainless steel cannot meet the requirements of anti-corrosion, it is necessary to constantly improve the anti-corrosive materials. For example, some non-metallic materials or some metal materials with good corrosion resistance can be used to enhance the protection. However, in the selection of materials, comprehensive factors such as the characteristics of the medium, temperature, pressure are need to be considered. HC technical team will choose the appropriate materials according to the user’s working conditions.

3.To apply with anti-corrosion surface engineering technology

Effective anti-corrosion coating on the surface of shell and tube heat exchanger can be designed, such as painting, which can effectively prevent the corrosion of the base material.

The corrosion of shell and tube heat exchanger will produce a series of serious consequences. Therefore, it is better for operators to know about the specific causes of corrosion in advance, so as to solve the corrosion problem based on the actual situation.

The shell and tube heat exchanger produced by HC has been widely used at home and abroad. According to user feedback, the equipment has long service life, super corrosion resistance, and is easy to clean and maintain. To make reasonable material selection on the basis of the actual application that users can rest easy, our engineers will fully take into account the factors of fluid, corrosion, cleaning, pressure drop and heat transfer efficiency during the design.

-

2026 / 02 / 13Skid-mounted Thermally Activated Advanced Oxidation Process (AOP) System for Chemical Wastewater Treatment

-

2025 / 12 / 29

Customized Shell and Tube Heat Exchanger for Syria Project

Customized Shell and Tube Heat Exchanger for Syria Project -

2025 / 11 / 01

HC Successfully Delivers Gas-Liquid-Sand Separator for Xinjiang Oilfield Project

HC Successfully Delivers Gas-Liquid-Sand Separator for Xinjiang Oilfield Project

- +86 158 6190 3617