In the petroleum and natural gas industry, horizontal and vertical three-phase separators play a crucial role in separating well fluids into gas, oil, and water phases. Regarding their working principles, these two types of separators exhibit some differences in design and operation.

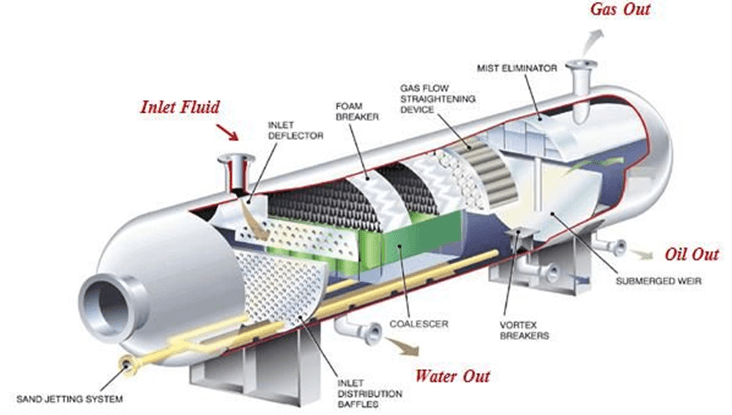

Horizontal Three-Phase Separator:

When well fluids enter the horizontal three-phase separator, initial separation of liquids and gases is triggered by an inlet diverter. The gas gradually rises within the separator, undergoes horizontal flow, and exits through a mist extractor to eliminate liquid droplets. Simultaneously, liquids enter the liquid collection area of the separator, where oil and emulsions separate, forming an independent oil "pad" above the free water. Through the control of a weir, the height of the oil-water interface is maintained, and the interface level controller regulates the water level. The oil eventually overflows the weir, and an interface level controller operates an oil discharge valve to control the oil level. Throughout this process, the interface level controller monitors the height of the oil-water interface, releasing sufficient water through another discharge valve to keep the interface at the predetermined height.

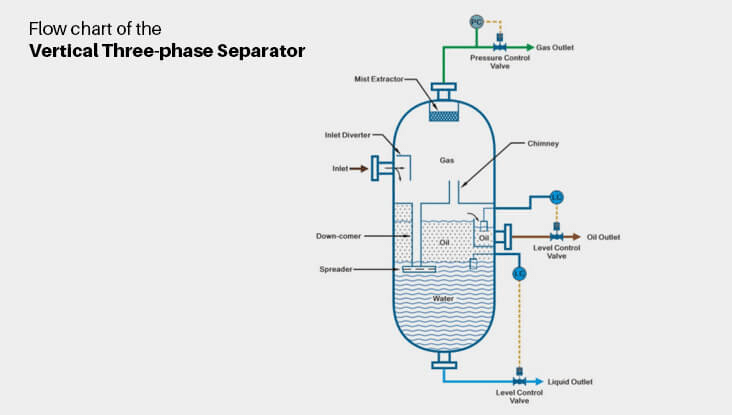

Vertical Three-Phase Separator:

Similarly, the vertical three-phase separator guides well fluids through a side entry diverter to initiate the initial separation of liquids and gases. Unlike the horizontal separator, the vertical separator includes a downcomer pipe to transfer liquid through the oil-gas interface. Additionally, the presence of a chimney helps balance gas pressure between the lower and gas sections, ensuring the maintenance of the system's pressure differential.

Horizontal and vertical separators both rely on the force of gravity to achieve effective separation of liquids, gases, and water. Throughout the separation process, the structures and functions of these separators are ingeniously designed to ensure efficient and reliable oil and gas production. Ultimately, the separated phases are further processed or transported to meet refining and processing requirements. The critical role of these separators in the oil and gas production process underscores their irreplaceability in the industry.

The selection of a three-phase separator involves a complex process considering multiple key factors, with the primary consideration being the characteristics of the fluid to be separated, including viscosity, density, flow rate, and liquid content. These characteristics directly impact the size and performance requirements of the separator.

During the selection process, operational conditions such as environmental temperature, pressure, and liquid level variations must be thoroughly considered to ensure that the chosen separator can adapt to various operating scenarios. Additionally, appropriate materials should be used in equipment design to address potential corrosion and wear. HC has over 20 years of experience in the manufacturing of three-phase separators. Please feel free to contact us if you have any specific requirements!

-

2025 / 12 / 29

Customized Shell and Tube Heat Exchanger for Syria Project

Customized Shell and Tube Heat Exchanger for Syria Project -

2025 / 11 / 01

HC Successfully Delivers Gas-Liquid-Sand Separator for Xinjiang Oilfield Project

HC Successfully Delivers Gas-Liquid-Sand Separator for Xinjiang Oilfield Project -

2025 / 08 / 20

HC Successfully Delivered Filter Coalescer Skid to Malaysia

HC Successfully Delivered Filter Coalescer Skid to Malaysia

- +86 158 6190 3617