In the oil and gas industry, separators are crucial for the initial processing of wellhead fluids, which typically contain a mixture of oil, gas, and water. Different types of separators are designed to efficiently separate these phases, ensuring the effective and safe handling of hydrocarbons. Here are the primary types of separators used in the industry:

Three-phase separators are among the most common types of separators used in oil and gas operations. These devices separate the fluid mixture into three distinct phases: oil, gas, and water. They come in various configurations, including horizontal and vertical, each suited to specific operational needs. The separation process relies on the differences in density between the three phases. Three-phase separators are essential in the initial processing stages, ensuring that each phase is correctly routed for further processing or disposal.

Two-phase separators, as the name suggests, separate the fluid mixture into two phases: gas and liquid (oil and water combined). These separators are simpler in design compared to three-phase separators and are typically used when the water content is minimal or when subsequent processing steps will handle the oil-water separation. Two-phase separators are commonly used in gas processing plants and other facilities where initial gas separation is prioritized.

Test separators are specialized devices used during well testing and evaluation phases. They can be configured as either two-phase or three-phase separators, depending on the specific requirements of the testing program. Test separators provide critical data on well performance, fluid composition, and flow rates, which are essential for reservoir management and production planning. These units are designed to handle varying flow rates and fluid compositions, making them versatile tools for exploration and production operations.

Production separators are used continuously during the production phase to separate the produced fluids into their constituent phases. These separators are designed for long-term operation and are optimized for efficiency and reliability. Production separators play a key role in ensuring the smooth operation of production facilities by effectively managing the flow of hydrocarbons and preventing issues such as hydrate formation and pipeline corrosion.

5. Horizontal Separators

Horizontal separators are typically used when space constraints are a concern or when handling large volumes of fluid. They offer a larger surface area for separation, which can be advantageous in certain applications. Horizontal separators can be designed as either two-phase or three-phase units and are commonly used in both onshore and offshore facilities.

6. Vertical Separators

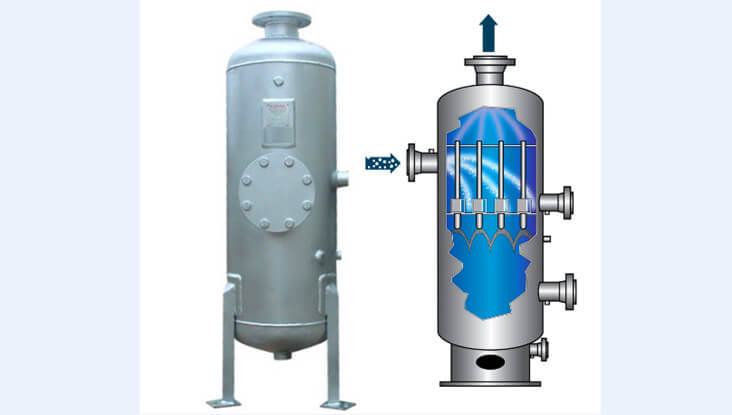

Vertical separators are often used in applications where there is a need for a compact footprint or where the fluid mixture has a high gas-to-liquid ratio. The vertical design allows for effective separation with a smaller surface area, making them ideal for offshore platforms and other space-limited environments. Vertical separators can also be configured as two-phase or three-phase units.

Cyclone separators use centrifugal force to separate gas and liquid phases. These separators are highly effective in removing fine droplets of liquid from gas streams and are often used as pre-separators to reduce the load on downstream separation equipment. Cyclone separators are commonly found in gas processing plants and other facilities where high-efficiency gas-liquid separation is required.

8. Scrubber Separators

Scrubber separators, also known as gas scrubbers, are used to remove liquid and solid contaminants from gas streams. They are essential in preventing damage to downstream equipment and ensuring the purity of the gas. Scrubber separators use a combination of mechanical and chemical processes to achieve high separation efficiency, making them vital components in gas processing and treatment facilities.

In conclusion, the choice of separator in the oil and gas industry depends on various factors, including the composition of the fluid mixture, the specific requirements of the processing facility, and operational considerations. Each type of separator plays a crucial role in ensuring the efficient and safe handling of hydrocarbons, contributing to the overall success of oil and gas production operations.

HC, as a professional manufacturer in the oil and gas industry, can customize separators of various specifications according to user needs. If you have any requirements, please feel free to contact us.

-

2025 / 12 / 29

Customized Shell and Tube Heat Exchanger for Syria Project

Customized Shell and Tube Heat Exchanger for Syria Project -

2025 / 11 / 01

HC Successfully Delivers Gas-Liquid-Sand Separator for Xinjiang Oilfield Project

HC Successfully Delivers Gas-Liquid-Sand Separator for Xinjiang Oilfield Project -

2025 / 08 / 20

HC Successfully Delivered Filter Coalescer Skid to Malaysia

HC Successfully Delivered Filter Coalescer Skid to Malaysia

- +86 158 6190 3617