Raw natural gas generally contains condensate, water or other impurities. If it is not treated, it will bring great hidden dangers to production and damage pipelines and equipment. Therefore, filter separator must be used for processing before the gathering and transportation of natural gas.

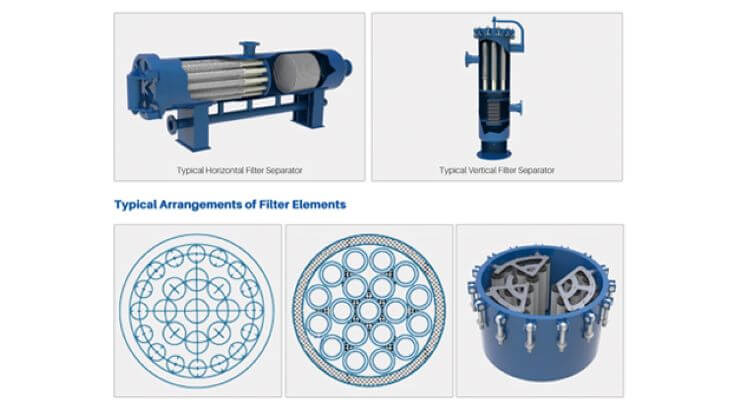

The filter separator is composed of a coalescing filter and a demister inside the vessel. Its working flow is as follows:

When natural gas enters the equipment, the larger size solid particles are filtered first by filters. The shape of the filter can be Y-shaped, single or duplex, depending on the amount of solids to be removed and whether the process allows you to take time to clean the filter elements (filter elements or basket). Mesh sizes range from 1/8 inch to 25 micron (smaller in special designs).

Secondly, coalescence filter is used to remove larger size liquid particles, but there are still smaller droplets under the action of inertia to reach the separation filter.

Finally, the separation filter is used to remove these smaller liquid particles from the fluid. At this time, the whole process of natural gas treatment is completed. In general, if the pre-filter and gas-liquid coalescer separator are used in low-temperature separation process, heating furnace and dehydration skid are no longer needed, which simplifies the purification process of natural gas, reduces the cost and brings considerable benefits.

The filter separator produced by HC Petroleum Equipment is made of high-quality material with excellent filtration effect, long service life, reasonable design, simple process and convenient operation, which can remove the condensate in the low-temperature natural gas and effectively prevent the precipitation of condensate in the transportation pipeline.

-

2025 / 12 / 29

Customized Shell and Tube Heat Exchanger for Syria Project

Customized Shell and Tube Heat Exchanger for Syria Project -

2025 / 11 / 01

HC Successfully Delivers Gas-Liquid-Sand Separator for Xinjiang Oilfield Project

HC Successfully Delivers Gas-Liquid-Sand Separator for Xinjiang Oilfield Project -

2025 / 08 / 20

HC Successfully Delivered Filter Coalescer Skid to Malaysia

HC Successfully Delivered Filter Coalescer Skid to Malaysia

- +86 158 6190 3617