In order to better solve the special needs of customers, to provide customers with a wider range of quality services, recently, HC Petroleum Equipment is working on develop of new cyclone and hydrocyclone separators

Cyclone Separator (Centrifugal separator)

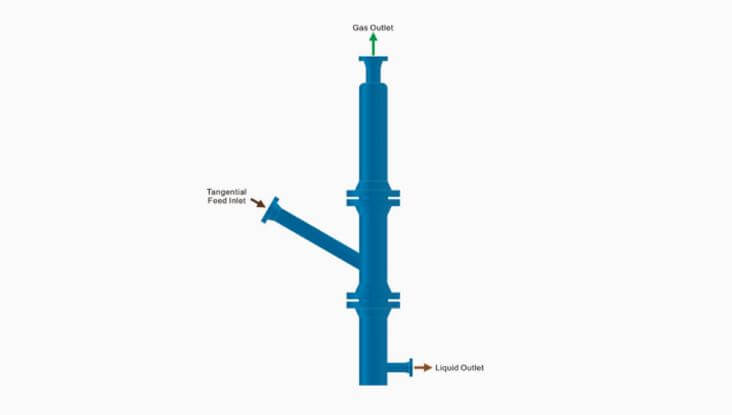

Cyclone separator (Centrifugal separator) is the special vessel performing separation function by gravitational and centrifugal (redial) forces. Cyclone separators are used in the separation process to separate gas from liquid or mixed liquids form each other. Thus, there are two main categories of cyclone separators, gas-liquid cyclone separator and liquid-liquid cyclone separator. Gas-liquid cyclone separators also known as gas-liquid cylindrical cyclone (GLCC), widely used in areas with high intensity of gas, for example, well testing. Liquid-liquid cyclone separators (LLSP) are used mainly used for separator oil from the water or gas condensate from water in oil and gas industries. Also, the LLSP also used in other processes depending on the operator’s requirement and design of the manufacturer. Centrifugal force may range from 5 times the gravitational force in large-diameter units to 2500 times the gravitational force in small, high-pressure units.

Our technology can be configured with cyclone baffles on equipment internals according to the manufacturer's calculation and design, and can be specially designed and installed on tangential raceway on the bottom.

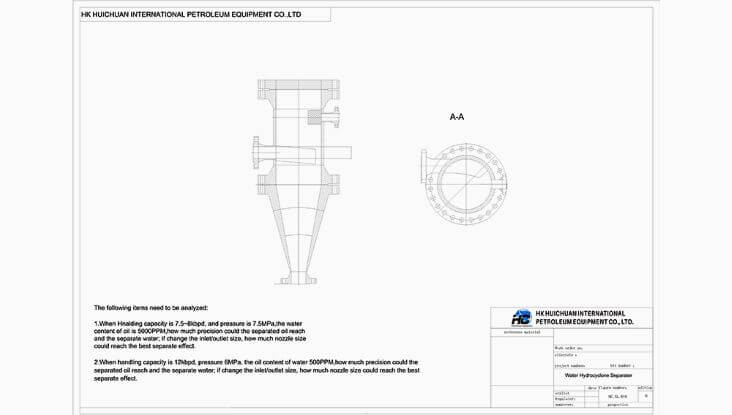

Hydrocyclone Separator

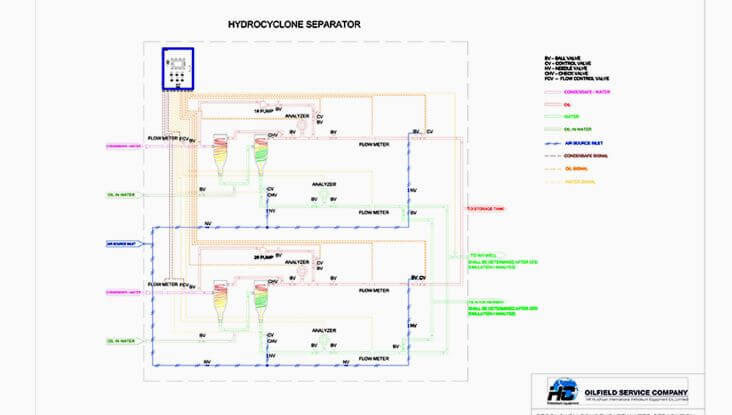

Hydrocyclone Separator is a specialized water treating separator, used in handling of the mixed fluids of light-phase and heavy-phase. In gas processing facility, hydrocyclone separator is used to separate light liquid from heavy liquid using gravitational and centrifugal (redial) forces.Hydrocyclones are skid-mounted, consisting of special-designed conical vessels, piping, flow control valves, booster pump, analyzers, flow meters, control and automation systems.

Our technical team is dedicated to developing more space-efficient structural solutions for customers, as well as longer working hours and more efficient equipment for oilfield processing and offshore platforms

-

2025 / 12 / 29

Customized Shell and Tube Heat Exchanger for Syria Project

Customized Shell and Tube Heat Exchanger for Syria Project -

2025 / 11 / 01

HC Successfully Delivers Gas-Liquid-Sand Separator for Xinjiang Oilfield Project

HC Successfully Delivers Gas-Liquid-Sand Separator for Xinjiang Oilfield Project -

2025 / 08 / 20

HC Successfully Delivered Filter Coalescer Skid to Malaysia

HC Successfully Delivered Filter Coalescer Skid to Malaysia

- +86 158 6190 3617